29

Make certain that the unit is disconnected from power

source before attempting to service or remove any

component.

CLEANING

Keep tool and workshop clean. Do not allow sawdust to

accumulate on the tool. Vacuum sawdust from drum feed

belt, roller bushings and cavities inside drum carriage.

LUBRICATION

• The shielded ball bearings in this tool are permanently

l ubricated at the factory. They require no further

ubrication.

• Periodically oil bushings on the pressure rollers and

feed table rollers.

TOOL REPAIRS

• If power cord is worn, cut, or damaged in any way, have

it replaced immediately.

• Replace worn abrasive when needed.

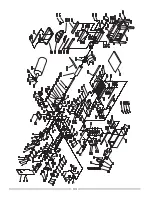

• Replace any damaged or missing parts. Use parts list to

order parts.

Any attempt to repair motor may create a hazard unless

repair is done by a qualified service technician. For further

information about repairs, please call the Customer ser-

vice at

1-866-599-5916 ext.2.

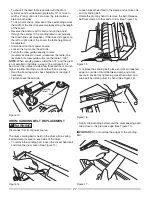

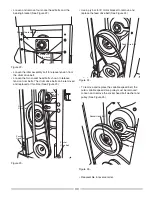

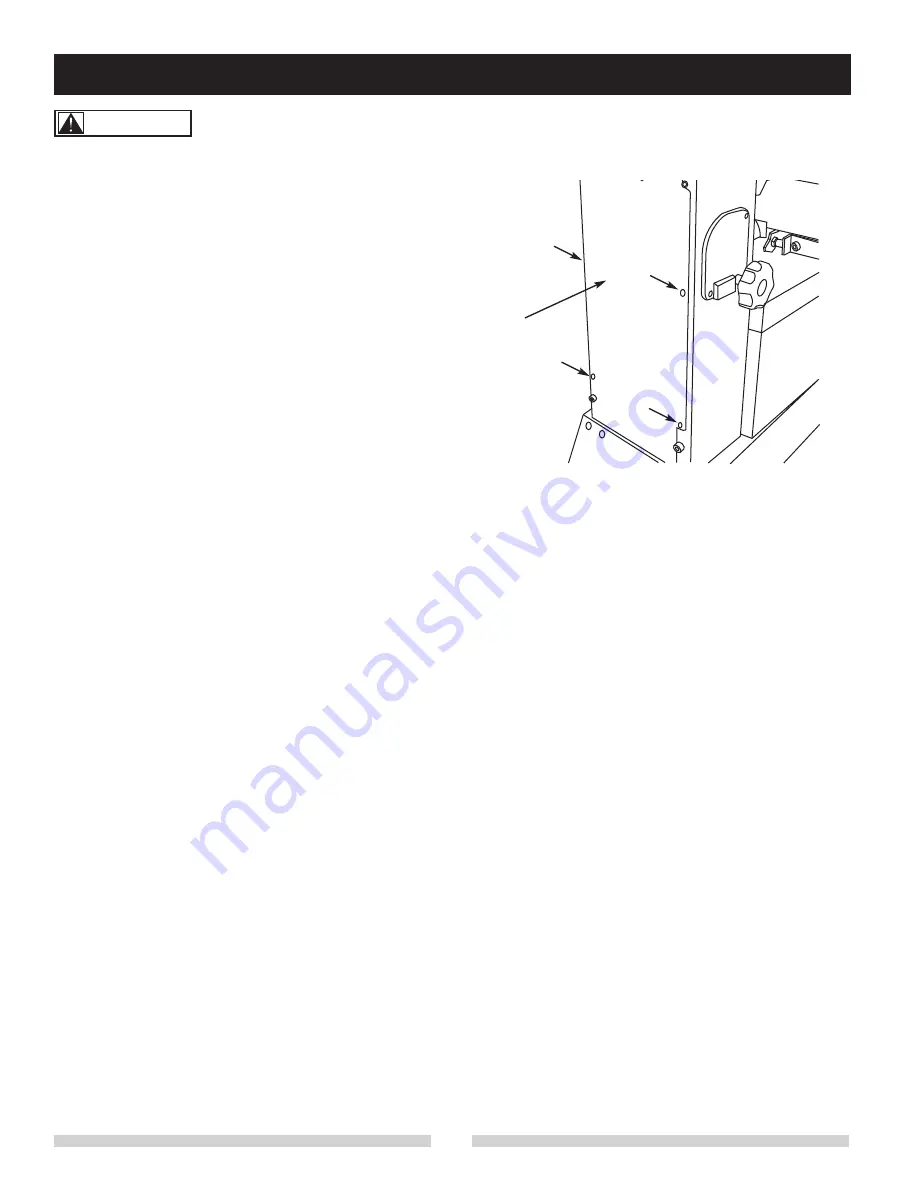

REMOVING AND REPLACING DRIVE BELTS

• Loosen and remove the six socket head bolts shown

and rear panel from column (See Figure 21).

MAINTENANCE

Panneau

arrière

Figure 21 -

WARNING