PNT152-B

ENGLISH

18

ACCESSORIES

Hex wrench 1

Filters 1

Socket spanner 1

Cleaning brush 1

BEFORE YOU START

Compatible Compressor & Air Tool - Guidelines for Proper Usage & Operation

Always ensure the use of appropriately matched air tools and compressors. Be sure

that the air compressor being used can supply the appropriate volume, pressure and

delivery rate of air to the tool(s) without running continuously. Using tools or

combinations of tools that together or separately require more than the air compressor

can deliver will reduce performance and could void the compressor or tool warranty.

AIR SYSTEM (Fig.6)

1. Always use clean, dry, regulated compressed air at 30 to 50 PSI

2. Do not exceed the maximum and minimum pressures. Operating the tool at the

wrong pressure (too low or too high) will cause excessive noise or rapid wear.

3. Keep hands and other parts of the body away from the tool’s discharge and

working areas when connecting the air supply.

4. It is recommended that a filter-regulator-lubricator be used, and that it be located

as close to the tool as possible..

5. If a filter-regulator-lubricator is not installed, place up to 6 drops of compressor oil

into the NPT inlet plug before each use.

6. If a filter-regulator-lubricator is installed, keep the air filter clean. A dirty filter will

reduce the air pressure to the tool, which will cause a reduction in efficiency, and

general performance.

7. For optimal performance, install a quick connector to the tool and a quick coupler

on the hose, if applicable.

8. Verify that all of the connections in the air supply system are sealed in order to

prevent air from leaking.

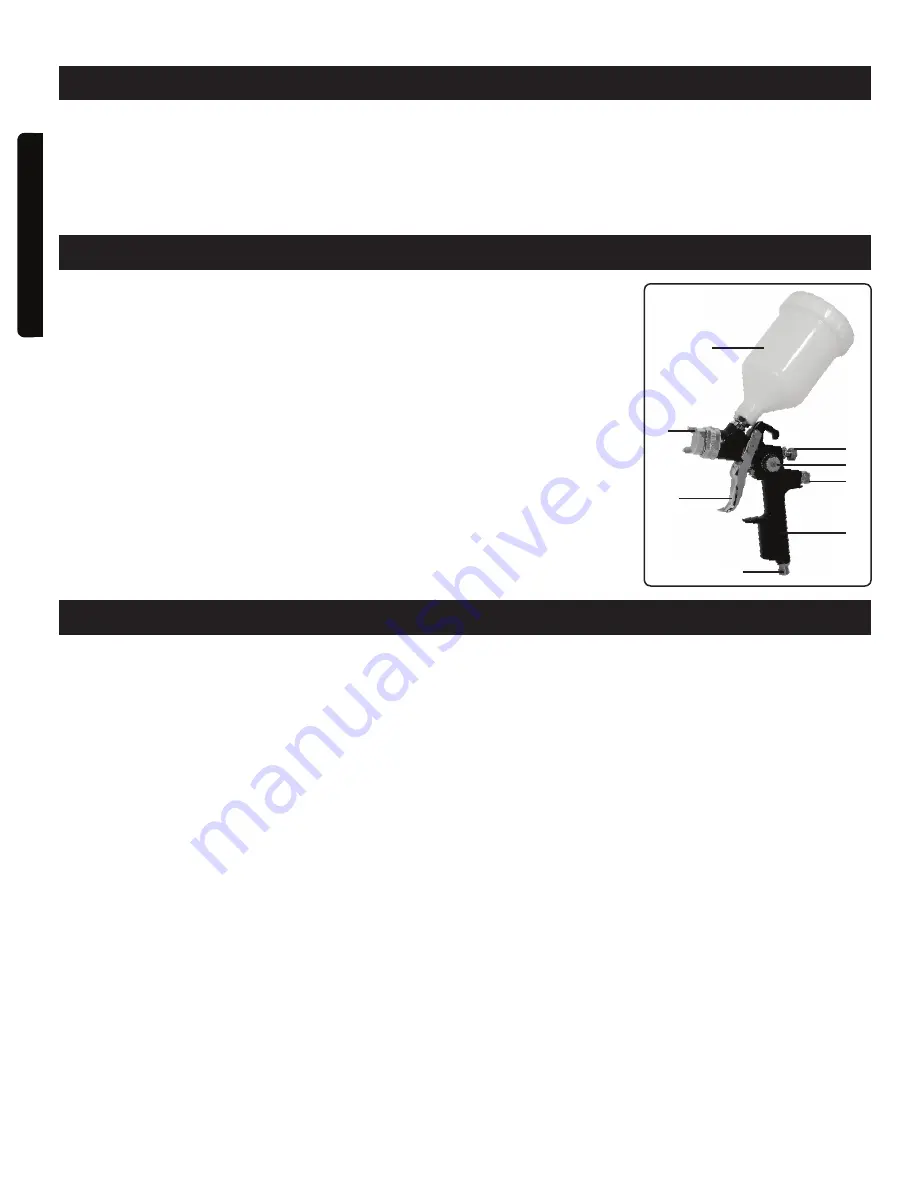

Figure 5 names the major components of the HAUSSMANN XPERT air powered

gravity-feed spray gun:

A. Air cap nozzle & needle

B. Air inlet joint

C. Gun body

D. Trigger

E. Air adjustment knob

F. Pattern adjustment knob

G. Fluid adjustment knob

H. 600 cc plastic cup

SPECIFICATIONS

FUNCTIONAL DESCRIPTION

SETUP & OPERATION

H

E

D

C

B

F

G

A

Fig.5