22

ENGLISH

ASSEMBLY

OPERATION

Hold the tool firmly and place the point of the driver bit in the screw head.

Apply forward pressure to the tool to the extent that the bit will not slip off

the screw and turn the tool on to start operation.

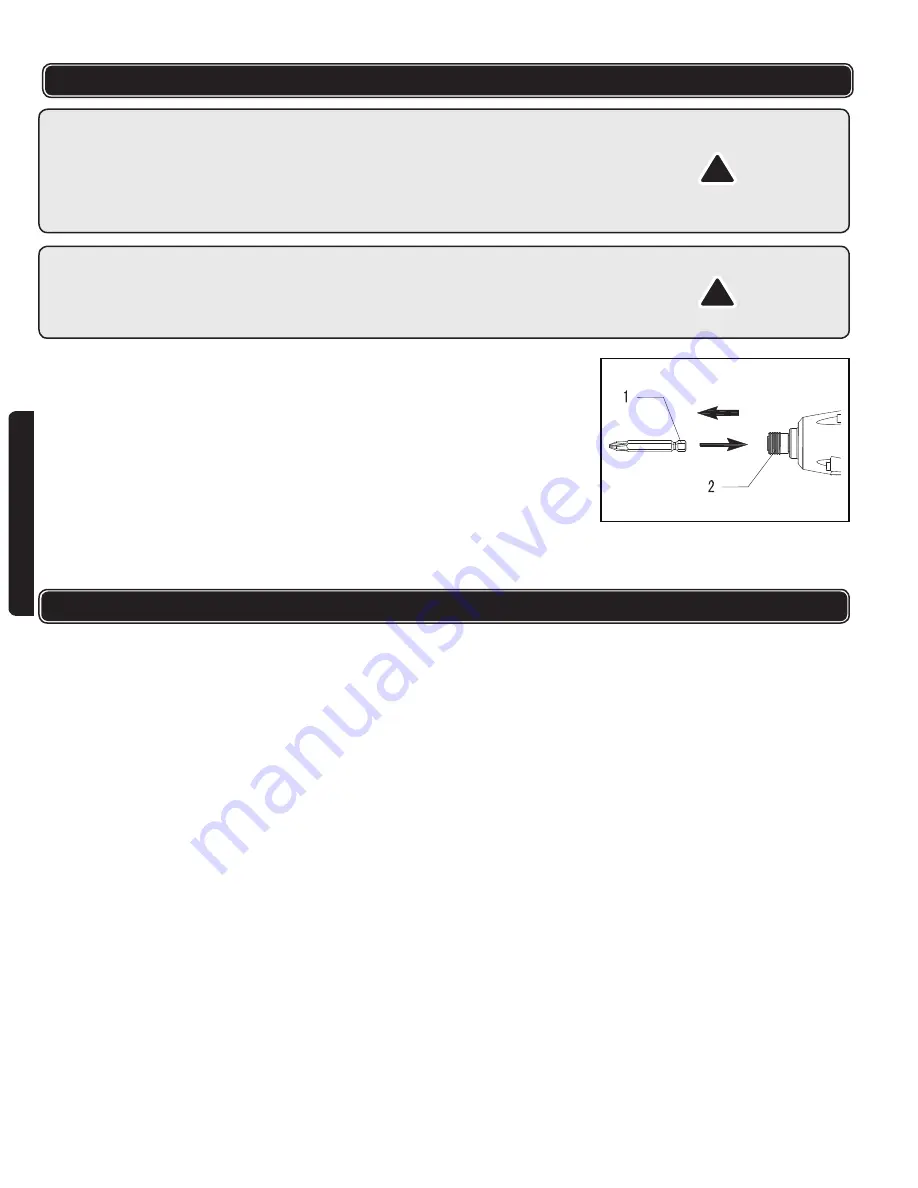

Installing or removing driver bit or socket bit

1. To install the bit, pull the sleeve (2) in the direction on the arrow and insert the

bit into the sleeve as far as it will go. Then release the sleeve to secure the bit.

2. To remove the bit, pull the sleeve in the direction on the arrow and pull the bit

out firmly.

(1. Bit 2. Sleeve)

NOTE:

If the bit is not inserted deep enough into the sleeve, the sleeve will not return to its

original position and the bit will not be secured. In this case, try re-inserting the bit

according to the instructions above.

!

CAUTION :

1) Always check the direction of rotation before operation.

2) Use the reversing switch only after the tool comes to a complete stop.

Changing the direction of rotation before the tool stops may damage the tool.

3) When not operating the tool, always set the reversing switch lever to the neutral

position.

!

CAUTION :

Always be sure that the tool is switched off and the battery pack is

removed before carrying out any work on the tool.

Use the reversing switch only after the tool comes to a complete stop.

Changing the direction of rotation before the tool stops may damage the tool.

NOTE:

1) Use the proper bit for the head of the screw/bit that you wish to use.

2) When fastening screws M8 or smaller, carefully adjust pressure on the switch

trigger so that the screw is not damaged.

3) Hold the tool pointed straight at the screw.

If you tighten the screw for a time longer than shown in the figures, the screw or

the point of the driver bit may be overstressed, stripped, damaged, etc. Before

starting your job, always perform a test operation to determine the proper fastening

time for your screw.

The fastening torque is affected by a wide variety of factors including the following.

After fastening, always check the torque with a torque wrench.

1. When the battery pack is discharged almost completely, voltage will drop and

the fastening torque will be reduced.

2. Failure to use the correct size driver bit or socket bit will cause a reduction in

the fastening torque.

3. Even though the torque coefficient and the class of bolt are the same, the

proper fastening torque will differ according to the diameter of bolt. Even

though the diameters of bolts are the same, the proper fastening torque will

differ according to the torque coefficient, the class of bolt and the bolt length.

4. The torque may be affected by the material to fasten, or the position in which

the tool is held.

5. Operating the tool at low speed will cause a reduction in the fastening torque.