– 19 –

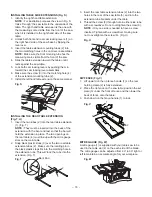

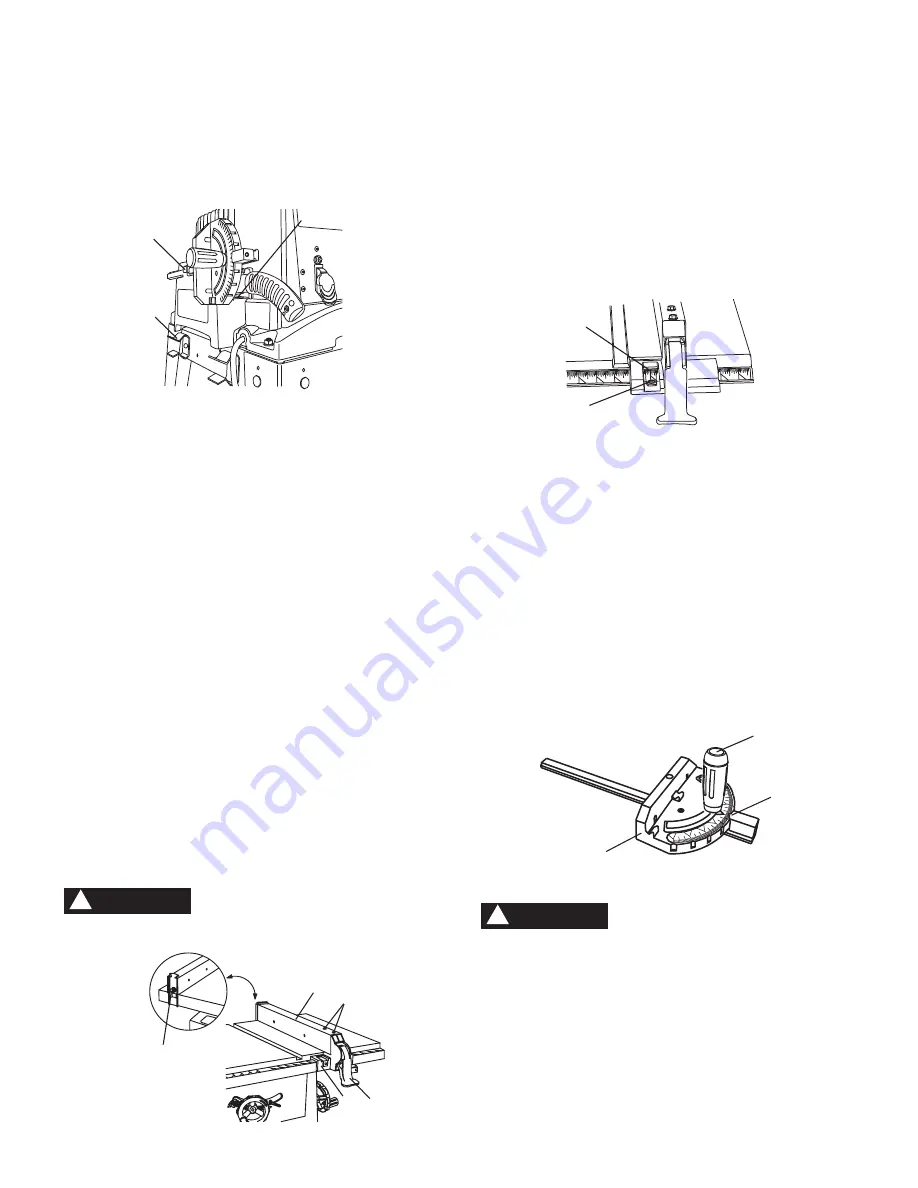

STORAGE (Fig. X)

Rip fence, Mitre gauge and Push stick

A storage bracket (1) for the rip fence is located on

the left side of stand. A storage holder (2) for the mitre

gauge is built on the left side of the saw base. The metal

push-stick storage bracket (3) is also attached to the left

side of the saw base.

RIP FENCE ADJUSTMENT (Fig. Y)

1. The fence (1) is moved by lifting up on the handle

(2) and sliding the fence to the desired location.

Pushing down on the handle locks the fence in

position.

2. Position the fence on the right side of the table, and

along one edge of the mitre gauge grooves.

3. Lock the fence handle. The fence should be parallel

with the mitre gauge groove.

4. If adjustment is needed to make the fence parallel to

the groove, do the following:

●

Loosen the two screws (3) and lift up on the

handle (2).

●

Hold the fence bracket (4) firmly against the front

of the saw table. Move the far end of the fence

until it is parallel with the mitre gauge groove.

●

Push the handle down and tighten both bolts.

5. If fence is loose when the handle is in the locked

(downward) position, do the following:

●

Move the handle (2) upward and turn the

adjusting nut (5) clockwise until the rear clamp is

snug. Do not turn the adjusting screw more than

1/4 turn at a time.

●

Over-tightening the adjusting screw will cause

the fence to come out of alignment.

Failure to properly align fence can cause “kickback” and

serious injury.

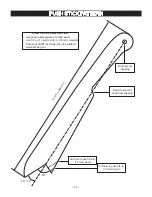

RIP FENCE INDICATOR ADJUSTMENT (Fig. Z)

1. The rip fence indicator (6) points to the

measurement scale. The scale shows the distance

from the side of the fence to nearest side of the

blade.

2. Measure the actual distance with a ruler. If there

is a difference between the measurement and the

indicator, adjust the indicator (6).

3. Loosen the screw (7) and slide the indicator to the

correct measurement on the scale. Tighten the

screw and remeasure with the rule.

ADJUSTING THE MITRE GAUGE (Fig. AA)

1. Loosen the lock handle (1) to allow the mitre body (2)

to rotate freely. Position the mitre body at 90° so the

positive detent secures its position. Tighten the lock

handle to hold the mitre body in position.

2. If the pointer (3) requires adjustment, loosen the

screw under the pointer with a screwdriver. Adjust

the pointer to 90° on the scale, then firmly tighten the

adjustment screw.

3. To change angles on the mitre gauge, loosen the

lock handle (1) and rotate the mitre body to the

desired angle as indicated by the scale. Secure in

position by tightening the lock handle.

ADJUSTING THE TABLE INSERT (Fig. BB)

To avoid serious injury, the table insert (2) must be

level with the table. If the table insert is not flush

with the table, adjust the two bolts (1) with a 4 mm

hex wrench until it is parallel with the table.

NOTE :

To raise the insert, turn the hex screws

counterclockwise, to lower the insert, turn the hex

screws clockwise. Do not remove the insert, adjustments

need to be made with the insert in place to get the

proper level.

Fig. X

2

1

3

WARNING

!

1

3

2

4

5

Fig. Y

6

7

Fig. Z

Fig. AA

30

75

60

45

3

1

2

WARNING

!