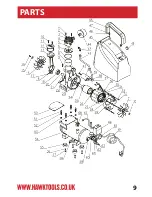

NO

PART

QTY

NO

PART

QTY

1 Bolt M6×25

2

35 Spring washer 4

1

2 Bolt M6×35

2

36 Tooth washer 4

1

3 Spring washer 6

4

37 Screw M3×6

2

4 Cylinder head

1

38 Spring washer 3

2

5 Circle

1

39 Nut M3

2

6 Valve plate subassembly

1

40 Capacitance

1

7 Cylinder seals

1

41 Tooth washer 8

1

8 Cylinder

1

42 Discharge pipe D10mm

1

9 Connection Stud

1

43 Elbow connecter

1

10 Screw M5×16

2

44 Air filter

1

11 Connecting rod cover

1

45 Fan cover

1

12 Piston ring

1

46 Big washer 8

2

13 Connecting rod

1

47 Bolt M

8

×12

2

14 Bolt M6×16

1

48 Handle

1

15 Big washer 6

1

49 Thermal protector

1

16 Fan

1

50 Base board

1

17 Bolt M4×20

1

51 Bolt M8×25

4

18 Spring washer 4

1

52 Washer 8

4

19 Bearing 6005-2RS

1

53 Flange nut M8

1

20 Pin 4x14

1

54 6L tank

1

21 Crank

1

55 Absorber

4

22 Bolt M8×35-left

1

56 Washer 5

4

23 Crankcase

1

57 Bolt M5×25

4

24 Bearing 6204-RS

1

58 Drain valve 1/4 inch

1

25 Rotor

1

59 Quick coupler

1

26 Stator subassembly

1

60 Pressure gauge 40

1

27 Bearing 6202-RS

1

61 Regulate valve

1

28 Corrugate washer 34

1

62 Three way connecter

1

29 Motor bracket

1

63 Safety valve

1

30 Circlip

1

64 Power cord

1

31 Fan

1

65 Pressure gauge 50

1

32 Bolt M5×105

4

66 Pressure switch

1

33 Spring washer 5

4

67 Release pipe

1

34 Screw M4×10

1

68 Checking valve

1

PARTS LIST

10

PART

ITEM

QTY

PART

ITEM

QTY

Summary of Contents for HWKAC1

Page 9: ...PARTS 9...