34

GB

Translation

If you however have not complied with the above, and if the dust has not imprin-

ted yet, the intervention of an authorized person for cleaning the plastic rollers is

necessary .

5.2 BY AUTHORIZED COMPANIES

No further interventions should be required during the warranty period, if using the

lift correctly, and maintaining the appropriate cleanliness of the track and observing

the annual revisions .

However, if irregularities occur, please contact the company that installed the lift .

After the warranty period, we recommend an annual check of the lift by a company

authorized by the manufacturer .

5.3 MAINTENANCE LIST

5.3.1 WEAR PARTS

Wear parts for which we recommend checking are:

- all plastic guide and support rollers

- the sprocket

- other items that would show visible signs of wear .

5.3.2 SAFETY DEVICES

For safety devices and parts, check both their integrity and that of their seals . If any

of this safety devices are not working correctly you may call the company that you

purchased the stair lift from . Only authorized companies are allowed to inspect the

safety devices .

MODEL HW11:

If the lift is not in use, it is absolutely necessary to protect

the drive unit against weather effects with the included

cover cap.

Summary of Contents for HW 10

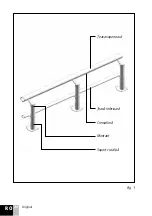

Page 4: ...4 D bersetzung Abb 1 Oberes Rohr Unteres Rohr Zahnstange St tze Fu st tze...

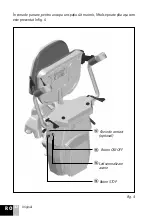

Page 5: ...5 D bersetzung Sitz Antrieb Zahnstange Schiene Ausgleich Abb 2...

Page 11: ...11 D bersetzung Abb 5 1 Drehsitzhebel...

Page 13: ...13 D bersetzung Abb 7...

Page 21: ...21 GB Translation Fig 1 Upper tube Lower tube Rack Beam Sole support for pole...

Page 22: ...22 GB Translation Lift Rolling mechanism Drive pinion Rail Stabilization mechanism Fig 2...

Page 28: ...28 GB Translation Fig 5 1 Swivel seat handle...

Page 30: ...30 GB Translation Fig 7...

Page 38: ...38 RO Original Fig 1 eavasuperioar eav inferioar Cremalier Montant Suport cu talp...

Page 47: ...47 RO Original Fig 7...