MOWER MAINTENANCE

Check the oil level daily before starting the engine and ensure that the

correct oil level is maintained. Refer to-‘Before Starting the Mower’

for oil checking and filling instructions.

Change the engine oil after the first 5 hours of operation and thereafter

according to the ‘Maintenance Schedule’:-

1. Drain fuel by running the engine until the fuel tank is empty.

2. Remove the spark plug lead.

3. Allow the engine to cool.

4. Drain the oil while the engine is warm.(Not hot)

5. Tip the mower over on to its left hand side thus ensuring that

the air cleaner is kept uppermost

to prevent engine damage.

6. Remove the oil filler dipstick and drain the oil into a suitable

container.

7. Refill with new oil of the recommended SAE viscosity grade.

(Refer to-‘Before Starting the Mower’)

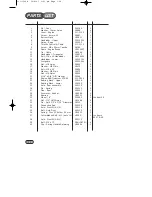

To service the air cleaner, loosen screw (1) and remove cover (2).

Remove cartridge (3) and clean by tapping gently on a flat surface. If

very dirty, replace.

- Do not use petroleum solvents.

- Do not use pressurised air.

- Do not oil the cartridge.

After servicing, install the cartridge into the cover. Insert the tabs on

the bottom of the cover into the slots in the bottom of the base (4). Tilt

the cover upwards and securely tighten the screw to the base.

1.22

1

2

3

4

Oil Service

Air Cleaner Service

111-1292 A 20/4/07 1:51 pm Page 1.22