27

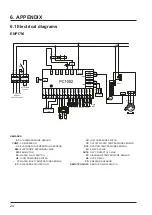

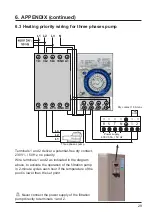

6. APPENDIX (continued)

REMARKS:

AT:

AIR TEMPERATURE SENSOR

OT:

OUTLET WATER TEMPERATURE SENSOR

COMP:

COMPRESSOR

SUT:

SUCTION TEMPERATURE SENSOR

CT:

EVAPORATOR TEMPERATURE SENSOR

4V:

4 WAYS VALVE

EEV:

ELECTRONIC EXPANSION VALVE

OUT2:

DRY CONTACT 16 A MAX

FM1-2:

FAN MOTOR

ET:

DISCHARGE TEMPERATURE SENSOR

FS:

WATER FLOW SWITCH

K2:

OUT 2 RELAY

HP:

HIGH PRESSURE SWITCH

PS:

PRESSURE SENSOR

IT:

WATER INLET TEMPERATURE SENSOR

ZL10:

INVERTER DC FAN BOARD

LP:

LOW PRESSURE SWITCH

CN:

CURRENT REACTOR

EMI:

PHASE CONTROLLER

REMOTE ON/OFF:

REMOTE ON/OFF SWITCH

ENPI13T

CN9

485B1

GND

3

RLY1

OUT2

OUT3

AC-N

1

OUT4

OUT5

485A1

12V

CN2

+12V

+5

V

0~

10

V

-O

U

T

P

W

M-

O

U

T

AI

12

AI/

D

I1

1

AI/

D

I1

0

AI/

D

I0

9

PWM-IN

AI/

D

I0

8

AI/

D

I0

7

AI/

D

I0

6

AI/

D

I0

5

AI/

D

I0

4

AI/

D

I0

3

AI/

D

I0

2

AI/

D

I0

1

0~

5V

-IN

485A2

12V

CN8

485B2

GND

GN

D

GN

D

GN

D

GN

D

GN

D

GN

D

GN

D

GN

D

GN

D

GN

D

GN

D

GN

D

GN

D

GN

D

GN

D

GN

D

GN

D

GN

D

R

FS

FS FS

LP

LP

H

P

H

P

LP

HP

t

5K

IT

IT IT

t

5K

OT

O

T

O

T

C

T

C

T

t

5K

CT

A

T AT

t

5K

AT

N

4V

1

3

2

4

5

6

7

8

01

ET

YEL

BLK

WHT

RED

R

t

50

K

4

ET

ET

SUT

SU

T

SU

T

t

5K

EE

V

5

R

S

T

N

R

ED

B

LK

W

H

T

BL

U

N

N

N

R

R

Remote

ON/OFF

A

B

G

N

D

12V

COMP

U V W

U

W

V

L3

L2

L1

C

B

A

EMI

R

T

A

B

C

S

T

R

S

T

S

R

S

T

YEL

RED

BLK

4

K2

2

N

N

N

N

K2

R

1

R S T N

Controller

YE

L

485

B-

R

ED

12

V

W

H

T

485

A+

PE

ACN

CN1

TP1

TP2

L3

N1

L5

ACL

CN4

FM1

ZL10

4V

2

4

N

R

FM2

PRS2

(WHT)

PRS1

(BLK)

NET2

(RED)

Y/G

BLU

BRN

BRN

F

N

K

2

1

3

2

4

5

6

7

8

02

4V

4V

4V

N

N

N

4V

N

N

R

F

1

5

WHT

RED

Pressure sensor

(PS)

RED

2

3

BLK

Detector

3

Y/

G

BL

U

B

R

N

Y

/G

BL

U

BR

N

4

6

7

8

1

3

5

1

3

5

Y/G

Y/G BLU BRN

2

BLU

4

BL

K

GN

D

6.

8K

400V / 3N~ / 50Hz

CN4

CN3

CN

C

N

4

C

N

3

3

R

1

2

16A max

Dry Contact

TO POWER SUPPLY