"R..7, F..7, K..7, S..7 Spiroplan

®

W Gear Units" - Operating Instructions

49

9

Lubricants

9

Lubricants

9.1

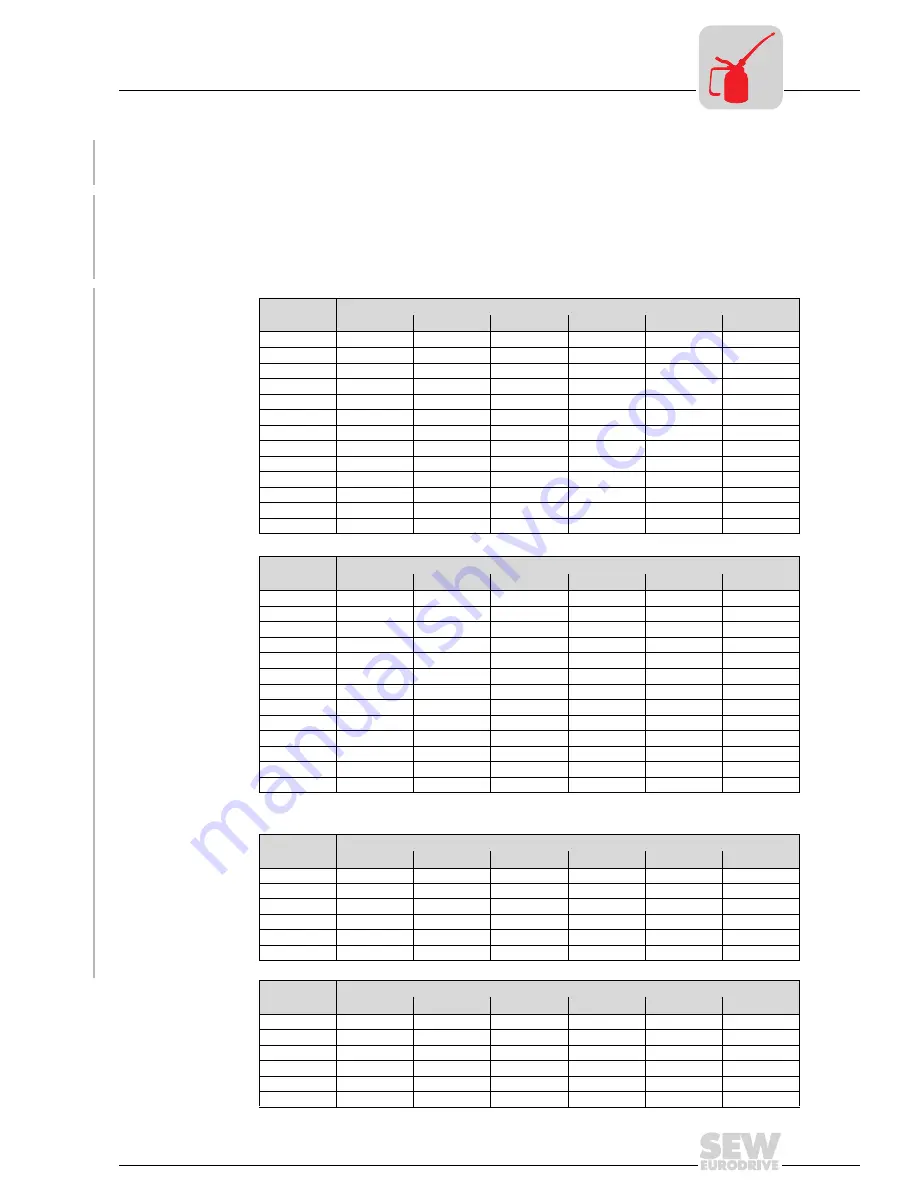

Lubricant fill quantities

The fill quantities are recommended values. The specific values vary depending on

number of stages and ratio. Pay close attention to the oil level plug to serve as indi-

cator for the correct amount of oil.

The following tables list the reocmmended values for the lubricant fill quantities in refe-

rence to mounting positions M1...M6.

Helical (R-)

gear units

1)

The larger gear unit in multi-stage gear units must be filled with the larger oil quantity.

Gear unit

type

Fill quantity in liters

M1

1)

M2

1)

M3

M4

M5

M6

R17/R17F

0.25

0.6

0.35

0.6

0.35

0.35

R27/R27F

0.25/0.4

0.7

0.4

0.7

0.4

0.4

R37/R37F

0.3/1

0.9

1

1.1

0.8

1

R47/R47F

0.7/1.5

1.6

1.5

1.7

1.5

1.5

R57/R57F

0.8/1.7

1.9

1.7

2.1

1.7

1.7

R67/R67F

1.1/2.3

2.6/3.5

2.8

3.2

1.8

2

R77/R77F

1.2 / 3

3.8 / 4.3

3.6

4.3

2.5

3.4

R87/R87F

2.3 / 6

6.7 / 8.4

7.2

7.7

6.3

6.5

R97

4.6/9.8

11.7/14

11.7

13.4

11.3

11.7

R107

6/13.7

16.3

16.9

19.2

13.2

15.9

R137

10/25

28

29.5

31.5

25

25

R147

15.4/40

46.5

48

52

39.5

41

R167

27/70

82

78

88

66

69

Gear unit

type

Fill quantity in liters

M1

1)

M2

1)

M3

M4

M5

M6

RF17

0.25

0.6

0.35

0.6

0.35

0.35

RF27

0.25/0.4

0.7

0.4

0.7

0.4

0.4

RF37

0.4/1

0.9

1

1.1

0.8

1

RF47

0.7/1.5

1.6

1.5

1.7

1.5

1.5

RF57

0.8/1.7

1.8

1.7

2

1.7

1.7

RF67

1.2/2.5

2.7/3.6

2.7

3.1

1.9

2.1

RF77

1.2 / 2.6

3.8/4.1

3.3

4.1

2.4

3

RF87

2.4 / 6

6.8/7.9

7.1

7.7

6.3

6.4

RF97

5.1/10.2

11.9/14

11.2

14

11.2

11.8

RF107

6.3/14.9

15.9

17

19.2

13.1

15.9

RF137

9.5/25

27

29

32.5

25

25

RF147

16.4/42

47

48

52

42

42

RF167

26/70

82

78

88

65

71

Gear unit

type

Fill quantitiy in liters

M1

M2

M3

M4

M5

M6

RX57

0.6

0.8

1.3

1.3

0.9

0.9

RX67

0.8

0.8

1.7

1.9

1.1

1.1

RX77

1.1

1.5

2.6

2.7

1.6

1.6

RX87

1.7

2.5

4.8

4.8

2.9

2.9

RX97

2.1

3.4

7.4

7

4.8

4.8

RX107

3.9

5.6

11.6

11.9

7.7

7.7

Gear unit

type

Fill quantity in liters

M1

M2

M3

M4

M5

M6

RXF57

0.5

0.8

1.1

1.1

0.7

0.7

RXF67

0.7

0.8

1.5

1.7

1

1

RXF77

0.9

1.5

2.4

2.5

1.6

1.6

RXF87

1.6

2.5

4.9

4.7

2.9

2.9

RXF97

2.1

3.6

7.1

7

4.8

4.8

RXF107

3.1

5.9

11.2

10.5

7.2

7.2