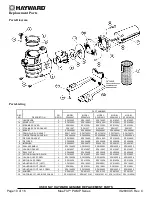

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Page 4 of 16

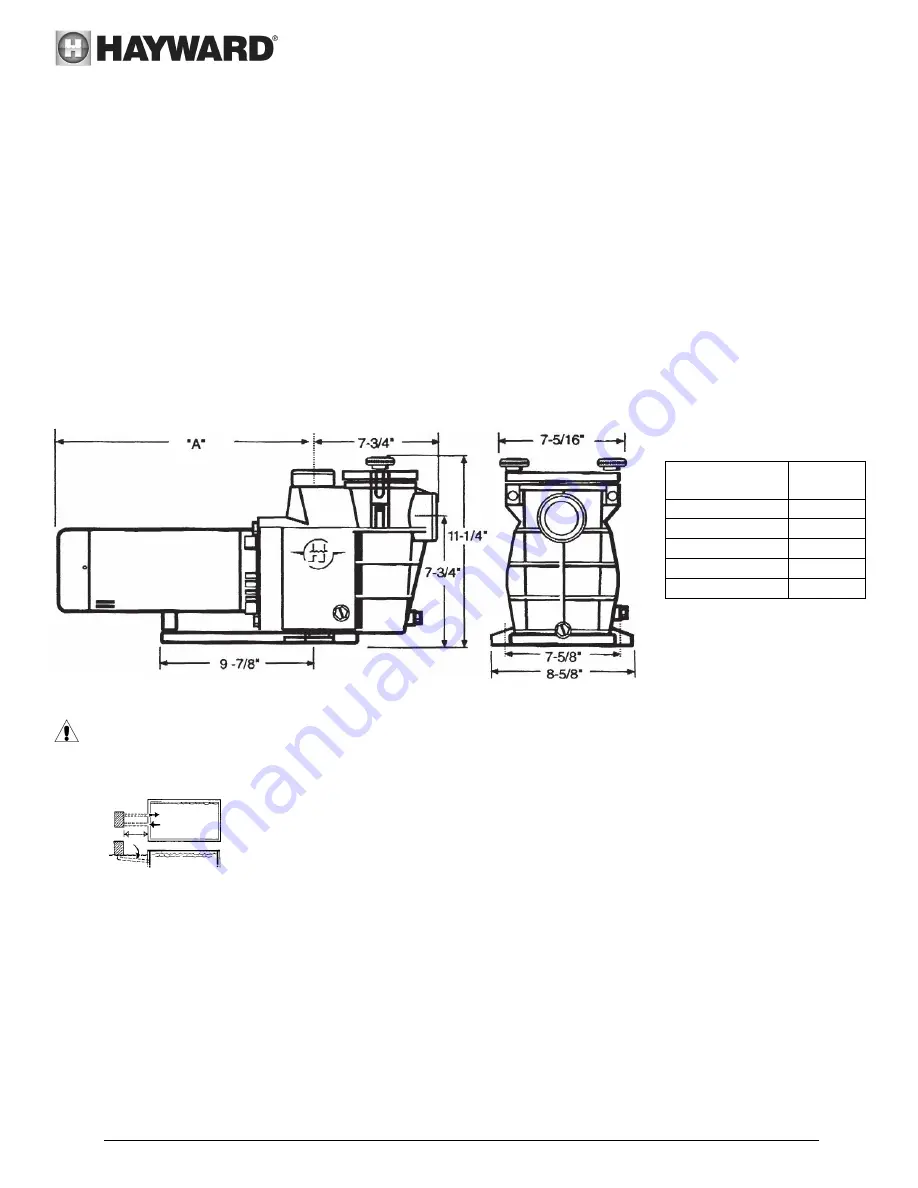

Max-Flo™ PUMP Series

IS2800X5 Rev. C

General Information

Introduction

This manual contains information for the proper installation and operation of the Hayward Max-Flo

™

Series. The

instructions in this manual

MUST

be followed precisely.

Failure to install according to defined instructions will void

warranty.

Product Benefits

Exclusive swing-aside knobs make strainer cover removal easy.

See-thru strainer cover lets you see when the basket needs cleaning.

Strainer basket incorporates an integral an integral handle for easy removal. Load extender ribbing ensures free flowing

operations.

Heavy-duty, high performance motor for quieter, cooler operation.

Service-ease design gives simple access to all internal parts.

Self-priming (suction lift up to 8’ above water level)

Product Specifications

Installation Instructions

WARNING

–

This product should be installed and serviced only by a qualified professional.

Pump Location

Locate pump as close to pool as practical and run suction lines as direct as possible to reduce friction

loss. Suction lines should have continuous slope upward from lowest point in line. Joints must be tight

(but not over-tightened). Suction line diameter must equal or be larger than the discharge line diameter.

Though the pump is designed for outdoor use, it is strongly advised to protect the electrical components

from the weather. Select a well-drained area, one that will not flood when it rains.

Do NOT install pump in a damp or

non-ventilated location.

Keep motor clean. Pump motors require free circulation of air for cooling.

Pump Mounting

Install pump on a firm, level base or pad to meet all local and national codes. Fasten pump to base or pad with screws or

bolts to further reduce vibration and stress on pipe or hose joints. The base MUST be solid, level, rigid, and vibration free.

Pump mount must:

Allow pump inlet height to be as close to water level as possible.

Allow use of short, direct suction pipe (to reduce friction losses).

Allow for gate valves in suction and discharge piping.

Be protected from excess moisture and flooding.

PUMP PART

NUMBER

LENGTH

“A”

SP2805X7

14

"

SP2807X10

14-3/8

"

SP2810X15

15-1/2

"

SP2815X20

16

"

SP2810X152

13-7/8

"