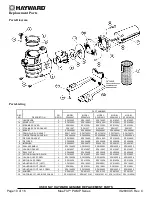

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Page 5 of 16

Max-Flo™ PUMP Series

IS2800X5 Rev. C

Allow adequate access for servicing pump and piping.

Incorporate a straight portion of pipe prior to pump inlet no less than (5) pipe diameters in length.

Pipe Sizing Chart

MAXIMUM RECOMMENDED SYSTEM FLOW RATE BY PIPE SIZE

Pipe Size

Flow rate

Water Velocity

Pipe Size

Flow rate

Water Velocity

inches [mm]

GPM [Liter/Min]

ft/sec [meters/sec]

inches [mm]

GPM [Liter/Min]

ft/sec [meters/sec]

1 ½”

50.76

8

2 ½”

119.40

8

[50]

[192]

[2.44]

[75]

[452]

[2.44]

2”

83.65

8

3”

184.32

8

[63]

[317]

[2.44]

[90]

[698]

[2.44]

NOTE

– No system should allow any higher than 8-ft/sec [2.44 meters/sec] water velocity. It is recommended that a minimum

length of piping, equivalent to 10 pipe diameters, be used between the pump suction inlet and any plumbing fittings.

WARNING –

Hazardous Pressure.

Pumps, filters, and other equipment/ components of a

swimming pool filtration system operate under pressure. Incorrectly installed and/or improperly tested

filtration equipment and/or components may fail resulting in injury and/or property damage.

Plumbing

Use

Teflon tape

to seal threaded connections on molded plastic components. All plastic fittings must be new or thoroughly

cleaned before use.

NOTE - Do NOT use Plumber’s Pipe Dope as it may cause cracking of the plastic components.

When applying

Teflon tape

to plastic threads, wrap the entire threaded portion of the male fitting with one to two layers of

tape. Wind the tape clockwise as you face the open end of the fitting, beginning at the end of the fitting. The pump suction

and outlet ports have molded-in thread stops.

Do NOT attempt to force hose connector fitting past this stop.

It is only

necessary to tighten fittings enough to prevent leakage. Tighten fitting by hand and then use a tool to engage fitting an

additional 1 ½ turns. Use care when using Teflon tape as friction is reduced considerably;

do NOT over-tighten fitting or

you may cause damage

. If leaks occur, remove connector, clean off old Teflon tape, re-wrap with one to two additional

layers of Teflon tape, and re-install connector.

Fittings

Fittings restrict flow. For better efficiency, use the fewest possible fittings (but at least two suction outlets). Avoid fittings

that could cause an air trap. Pool and spa fittings MUST conform to the International Association of Plumbing and

Mechanical Officials (IAPMO) standards.

Use a non-entrapping suction fitting in pool (multiple drains) or double suction

(skimmer and main drain).

Electrical

WARNING –

All wiring must be done by a licensed electrician and must conform to all

local and national codes and regulations.

WARNING –

Ground and bond motor before connecting to electrical power supply. Failure

to ground and bond pump motor can cause serious or fatal electrical shock hazard.

WARNING –

Do NOT ground to a gas supply line.

WARNING –

To avoid dangerous or fatal electrical shock, turn OFF power to motor before

working on electrical connections.

WARNING –

Ground Fault Circuit Interrupter (GFCI) tripping indicates electrical problem. If GFCI trips and

won’t reset, consult electrician to inspect and repair electrical system.

WARNING –

Fire Hazard.

Match supply voltage to motor nameplate voltage.