USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

8

Maintenance

Clean strainer basket regularly. Do NOT strike basket to clean. Inspect strainer cover gasket regularly and

replace as necessary.

Hayward pumps have self-lubricating motor bearings and shaft seals. No lubrication is necessary.

Keep motor clean. Insure air vents are free from obstruction to avoid damage. Do NOT use water to hose off

motor.

Occasionally, shaft seals must be replaced, due to wear or damage. Replace with genuine Hayward seal

assembly kit. See “Shaft Seal Change Instructions” in this manual.

Storage/Winterization

WARNING

–

Separation Hazard. Purging the system with compressed air can cause components to

explode, with risk of severe injury or death. To avoid, do not purge the system with compressed air. Use only a low

pressure (below 5 PSI), high volume blower when air purging the pump, filter, or piping.

NOTICE

–

Allowing the pump to freeze will void the warranty.

NOTICE

–

Use ONLY propylene glycol as antifreeze in your pool/spa system. Propylene glycol is non-toxic and will

not damage plastic system components; other anti-freezes are highly toxic and may damage plastic components in

the system.

Drain all water from pump and piping when expecting freezing temperatures or when storing pump for a long time

(see instructions below).

Keep motor dry and covered during storage. To avoid condensation/corrosion problems, do NOT cover or wrap pump

with plastic film or bags.

Storing Pump for Winterization

WARNING

–

Electrical Hazard

-

Failure to disconnect power may result in serious personal injury or

death. To avoid, turn OFF power to motor before draining pump.

1.

Drain water level below all inlets to the pool.

2.

Remove drain plugs from bottom of strainer body, and remove strainer cover from strainer housing.

3.

Disconnect pump from mounting pad, wiring system (after power has been turned OFF), and piping system.

4.

Once the pump is drained of water, re-install the strainer cover and drain plugs. Store pump in a dry area.

Shaft Seal Change Instructions

IMPORTANT SAFETY INSTRUCTIONS

PLEASE READ AND FOLLOW ALL INSTRUCTIONS

WARNING

–

Electrical Hazard

-

Failure to disconnect power may result in serious personal injury or

death. To avoid, turn OFF power to motor before servicing pump.

NOTICE-

Only qualified personnel should attempt rotary seal replacement. Contact your local authorized

Hayward Dealer or service center if you have any questions.

Exercise extreme care in handling both the rotating and the stationary sections of the two-part replacement seal. Foreign

matter or improper handling will easily scratch the graphite and ceramic sealing surfaces.

Removing the Motor Assembly

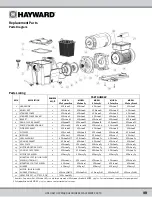

(See Parts Diagram on page 10 of this manual for pump component locations.)

1.

Remove the four (4) 3/8" x 2" housing cap screws which hold the motor assembly to the

pump/strainer housing.

2.

Slide the motor assembly out of the pump/strainer housing, exposing the diffuser. Pull the diffuser

off of the seal plate, exposing the impeller. (The diffuser may remain in the pump/strainer housing.

To remove, pull it straight out of the pump/strainer housing.)