Page

e 12 of 36

4.12.

Inte

The interfa

procedure

1.

TURN

2.

Loose

(Figur

3.

Disco

4.

Loose

moun

5.

Disco

Apply

6.

Moun

7.

Conne

sectio

suitab

motor

tight c

may b

8.

Moun

9.

Reinst

tighte

10.

Instal

protec

11.

Apply

The follow

rface Wal

ace can also b

e.

OFF THE ELEC

en the two scre

re 4.12-1)

nnect the sho

en the three sc

ting plate to g

nnect the sho

y electrical tap

t the wall mou

ect the interfa

on 5.2 to the m

ble for the inst

r drive and thr

cordgrip, appr

be up to 500 fe

t the user inte

tall the interfa

en the three sc

l the blank co

ct internal ele

y power to the

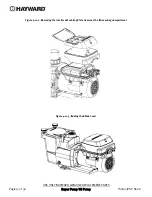

wing diagrams

Figur

USE ONLY H

l Mountin

be wall mount

CTRICAL POWE

ews securing

ort cable that e

crews securin

gain access to

ort cable on th

pe to the expo

unt plate, SP3

ace cable as sh

motor drive RS

tallation locat

rough the slot

ropriately size

eet in length.

erface to the w

ace mounting

crews to secur

over, SP3200D

ctronics. (Figu

system and re

s illustrate the

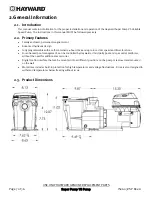

re 4.12-1: Rem

HAYWARD G

Super P

g

ted using the

ER AT THE CIR

the user inter

extends out fr

g the interface

o the drive wir

e interface m

sed conducto

3200DR10, in t

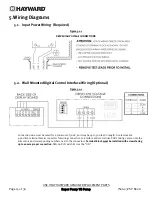

hown in the W

S485 terminal

tion. The cabl

t provided on

ed for the cabl

(Figure 4.12-4

wall mount pla

plate, taking

re.

DR9, on the mo

ure 4.12-3)

esume norma

interface wal

moving the Dig

GENUINE RE

Pump VS Pu

parts supplied

RCUIT BREAKE

rface to the mo

rom the motor

e mounting pl

ring compartm

ounting plate

ors. (Figure 4.1

the desired lo

Wall Mounted

block and use

e must be rou

the backside

le being used

4)

ate, SP3200D

care to make

otor drive in t

al operation.

ll mounting pr

gital Control I

PLACEMENT

ump

d in the optio

R.

otor drive and

r drive to the u

late to the mo

ment. (Figure 4

from the RS4

12-2)

ocation. (Figur

Digital Contro

er interface PC

uted through t

of the wall mo

, to seal the le

R10, using the

sure it is prop

he desired ori

rocedure.

nterface for W

T PARTS

nal wall moun

d remove the u

user interface

otor drive and

4.12-2)

485 terminal b

re 4.12-4)

ol Interface Wi

CB. Use multi

the left side co

ount plate, SP

eft side condu

e two screws.

perly aligned w

ientation. Thi

Wall Mounting

IS2603V

nt kit using th

user interface

. (Figure 4.12-

remove the in

block on the d

iring diagram

-conductor, ja

onduit openin

P3200DR10. U

uit opening. C

(Figure 4.12-4

with the moto

is cover is imp

g

VSP Rev-A

e following

e.

-1)

nterface

rive PCB.

shown in

acketed cable

ng on the

Use a liquid

Cable used

4)

or drive, and

portant to