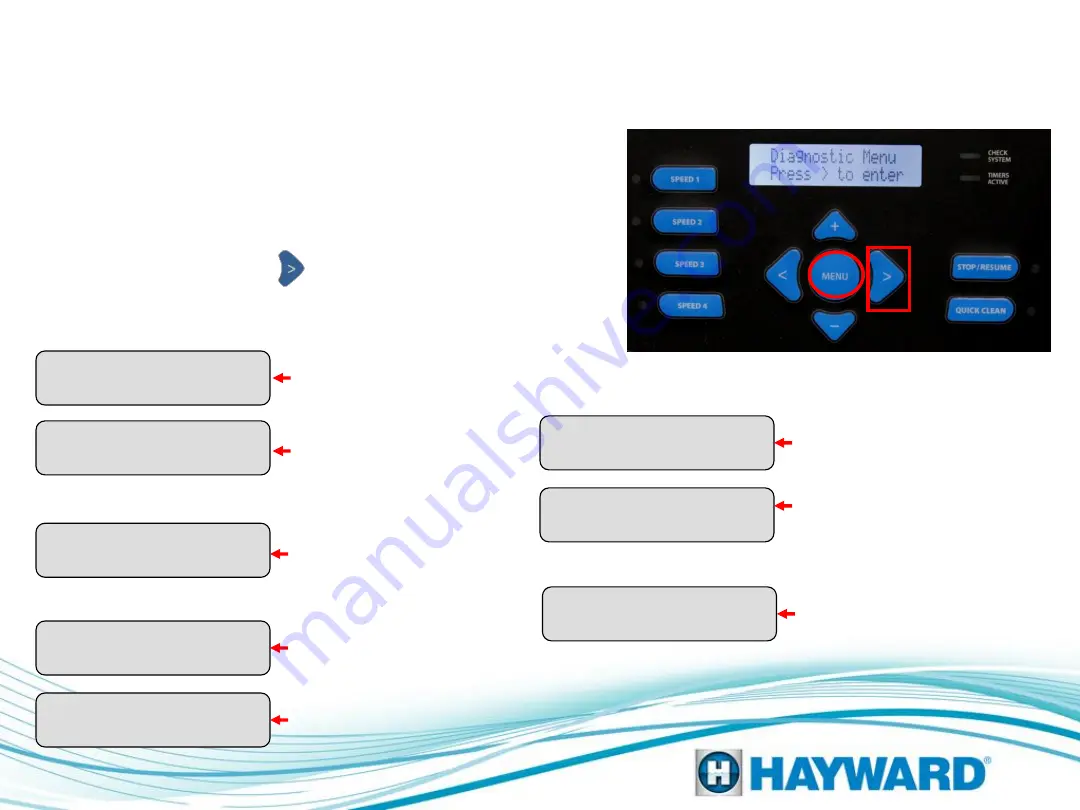

Diagnostics

1.

Press the Menu button until the Diagnostic screen

appears

(fig 54).

This menu provides important

information about the performance of the pump that can

be used during troubleshooting. Below are the different

screens and their meaning. These are all real-time

displays. Press the button to view information.

Display Revision

1.01

Drive Serial Number

DET-3581200032

DC Bus Voltage

Within Range

Motor Current

1.1A (8.5A Max)

Power Usage

225W (1700W Max)

Comm Rev: 0.96

Drv Rev: 2.00

Drive Temperature

67

°

C (110

°

C Max)

Event Log

Press + to View

Displays motor drive

serial #.

Displays status of internal

DC bus voltage.

Real-time display of

motor input current.

Estimated Real-time display

of pump power usage.

Real-time display of

motor driver

temperature.

By pressing the + button you

will see the last 20 errors and

or trip conditions, as well as

the amount of time that has

elapsed since the condition

occurred.

Page 35

Figure 54

Displays the firmware

revision of the display

PCB.

Displays firmware

revisions of the motor

drive and drive

communication PCBs.