Page 3

IMPORTANT SAFETY INSTRUCTIONS

Before installing or servicing this electrical equipment, turn power supply OFF.

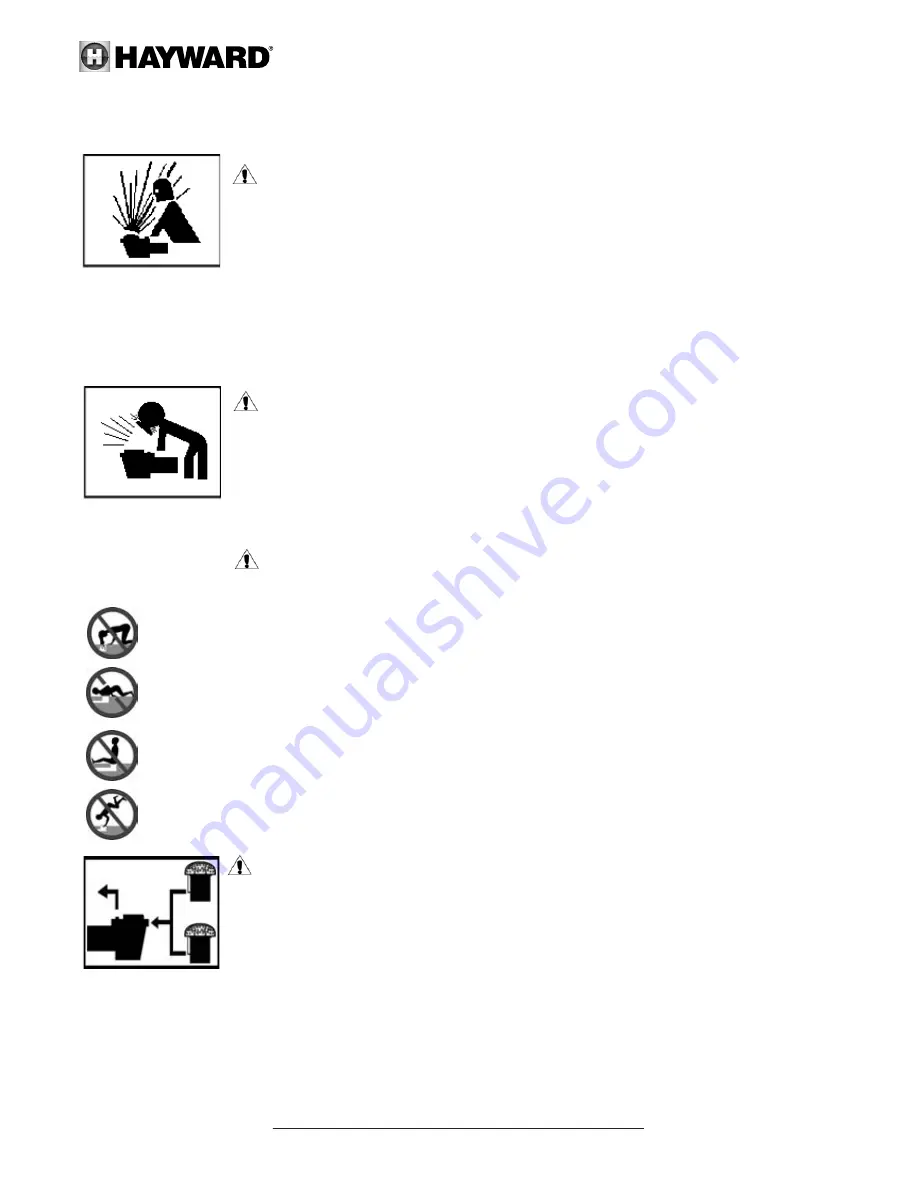

WARNING

–

Hazardous Pressure.

Pool and spa water circulation systems operate

under hazardous pressure during start-up, normal operation, and after pump shut-off. Stand

clear of circulation system equipment during pump start-up. Failure to follow safety and

operation instructions could result in violent separation of the pump housing and cover due to

pressure in the system, which could cause property damage, severe personal injury, or death.

Before servicing pool and spa water circulation system, all system and pump controls must be

in the off position and the filter manual air relief valve must be in the open position. Before starting the system pump,

all valves must be set in a position to allow system water to return back to the pool. Do not change the filter control

valve position while the system pump is running. Before starting the system pump, fully open the filter manual air

relief valve. Do not close the filter manual air relief valve until all the air is expelled and a steady stream of water is

discharged from the valve. All suction and discharge valves

MUST

be

OPEN

when starting the circulation system.

Failure to do so could result in severe personal injury and/or property damage.

WARNING

–

Separation Hazard.

Failure to follow safety and operation instructions

could result in violent seperation of pump components. Strainer cover must be properly secured

to pump housing with strainer cover lock ring. Before servicing pool and spa circulation system,

all system and pump controlls must be in off position and filter manual air relief valve must be in

open position. Do not operate pool and spa circulation system if system components are not

assembled properly, damaged, or missing. Do not operate pool and spa circulation system unless

filter air relief valve body is in locked position in filter upper body. All suction and discharge valves

MUST

be

OPEN

when

starting the circulation system. Failure to do so could result in severe personal injury and/or property damage.

WARNING -

Suction Entrapment Hazard.

Suction in suction outlets and/or

suction outlet covers, which are damaged, broken, cracked, missing, or unsecured cause sever injury and/or

death due to the following entrapment hazards.

Hair Entrapment

- Hair can become entangled in suction outlet cover.

Limb Entrapment

- A limb inserted into an opening of a suction outlet sump or suction outlet cover that is

damaged, broken, cracked, missing, or not securely attached can result in a mechanical bind or swelling of

the limb.

Body Suction Entrapment

- A differential pressure applied to a large portion of the body or limbs can

result in an entrapment.

Evisceration/Disembowelment

- A negative pressure applied directly to the intestines through an

unprotected suction outlet sump or suction outlet cover which is damaged, broken, cracked, missing, or

unsecured can result in evisceration/disembowelment.

Mechanical Entrapment

- There is potential for jewelry, swimsuits, hair decorations, fingers, toes, or

knuckles to be caught in an opening of a suction outlet cover resulting in mechanical entrapment.

WARNING -

To Reduce the risk of Entrapment Hazards:

- When outlets are small enough to be blocked by a person, a minimum of two functioning

suction outlets per pump must be installed. Suction outlets in the same plane (i.e. floor or wall),

must be installed a minimum of 0.91 metre or three feet (3’) apart, as measured from near point

to near point to avoid duel blockage by a user.

- Duel suction fittings shal not be located on seating areas or on the backrest for such seating

areas.

- Never use pool or spa if any suction outlet component is damaged, broken, cracked, missing, or not securely attached.

- Replace damaged, broken, cracked, missing, or not securely attached suction outlet components immediately.

- In addition to installing two or more suction outlets per pump, follow all national, state and local codes applicable.

- Installation of a vacuum release or vent system, which relieves entrapping suction, is recommended.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

TriStar Variable Speed Pump

30-LITINSB004 Rev-B