11

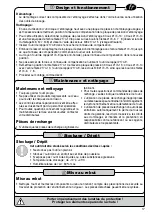

You must wear safety glasses.

Secure separate parts from falling off.

• Remove the transmission, detaching and removing all at-

tached parts for this.

• Remove the faulty clutch.

• Check (visually, by hand) the surface of the dual mass fly-

wheel for wear and tear (marks, temperature-related damage

etc. and clearance).

• If necessary, replace the dual mass flywheel.

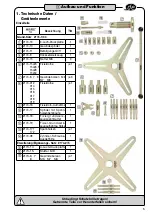

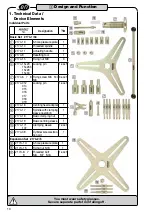

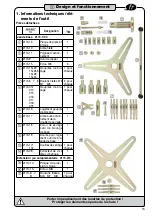

3. Application

Installation:

• To centre the clutch disc accurately, use basic fixing tool

2147-16 17 18 19 with appropriate clamping sleeve

2174-171 or 172, and, for vehicles with a guide bearing, a

suitable locking pin 2174-012 to 019, or, for BMW, locking

pins 2174-15x23 to 2174-15x34 (observe diameters) from

the SAC Clutch Alignment Tool Set HAZET 2174-1/34

(Fig. 1).

• Insert clutch disc with tool combination 2147-16 17 18

19 and 2174-171 or 172.

• To install the clutch pressure plate, use suitable threaded

bolts 2174-6 7 8 (observe thread size, M6 M7 M8).

• 3 threaded bolts 2174-6 7 8 (always the shorter thread

end) turned 120° with the most commonly used SAC

clutches / 4 threaded bolts 2174-6 7 8 turned 90° e.g. with

MERCEDES-BENZ model 169, are to be screwed hand-tight

into the dual mass flywheel (Fig. 2).

• Select a suitable pressure plate – 3-hole 2174-13; 4-hole

2174-14.

• Screw threaded spindle 2147-10 with actuating handle

2174-11 into pressure plate 2174-13 14 and reset this

completely.

• Next, screw these connected tools in place above the clutch

pressure plate using nuts M8 2174-15 (flush) with threaded

bolts 2174-6 7 8 (Fig. 3).

• Press the diaphragm spring of the clutch pressure plate

down with threaded spindle 2147-10 until the limit stop is

reached (clutch pressure plate is now resting gap-free on

the dual mass flywheel) (Fig. 4).

• Screw the screws of the clutch pressure plate into the free

threaded holes on the dual mass flywheel.

• Reset threaded spindle 2147-10 completely, relaxing the

diaphragm spring in a controlled fashion (Fig. 5).

• Undo nuts M8 2174-15, pressure plate 3 hole 2174-13;

4 hole 2174-14 with threaded spindle 2147-10, remove

threaded bolt 2174-6 7 8.

• Insert the remaining screws of the clutch pressure plate

and tighten all screws with the torque specified (follow

manufacturer's instructions).

• Remove fixing tools and any locking pins 2174-15x23 to

2174-15x34 used, if necessary; with the help of the provided

cylinder screw extraction aid 2174-08.

2. Before using the

SAC clutch alignment tool

HAZET 2174-1/34

nOTe:

Follow the instructions provided

by the vehicle manufacturer dur-

ing any work you do.

3

Design and Function

Fig. 2

Fig. 3

Fig. 1

Fig. 4

Fig. 5

Summary of Contents for SAC

Page 18: ...18 Notizen Notes ...

Page 19: ...19 Notizen Notes ...