HAZET-WERK

Hermann Zerver GmbH & Co. KG

;

Güldenwerther Bahnhofstrasse 25 – 29 · 42857 REMSCHEID · GERMANY

[

+49 (0) 21 91 / 7 92-0 ·

\

+49 (0) 21 91 / 7 92-375 ·

^

hazet.de ·

]

info@hazet.de

HAZET-WERK

Hermann Zerver GmbH & Co. KG

;

Güldenwerther Bahnhofstrasse 25 – 29 · 42857 REMSCHEID · GERMANY

[

+49 (0) 21 91 / 7 92-0 ·

\

+49 (0) 21 91 / 7 92-375 ·

^

hazet.de ·

]

info@hazet.de

•

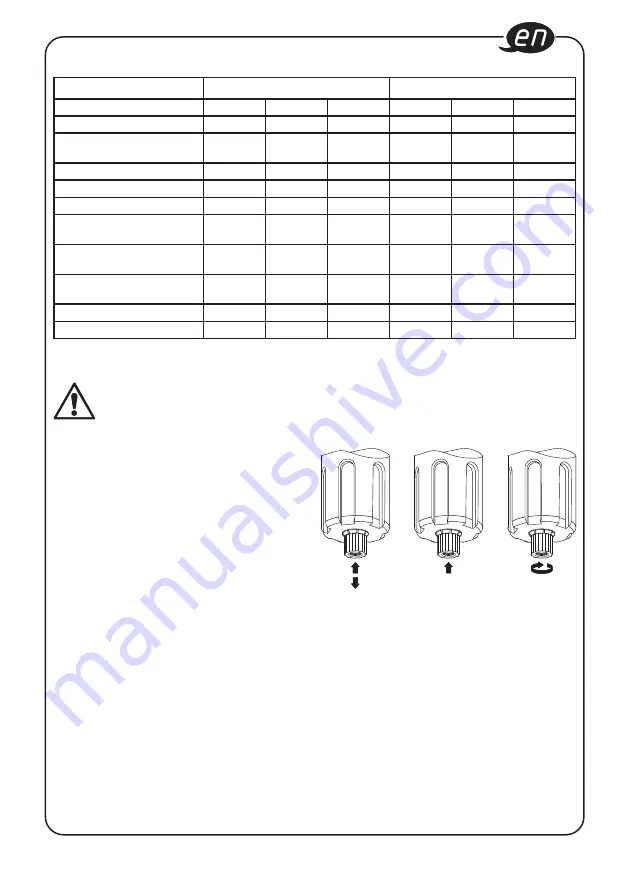

Condensate drain

There is a condensate drain valve

4

in the lower

part of the filter cup.

1

2

3

• Position

1

– semi-automatic condensate drain:

The valve knob is in central free position

– valve closes if system is under pressure,

condensate is drained only during the

absence of pressure

• Position

2

– manual condensate drain:

Push the valve knob up to drain condensate

manually even under pressure.

• Position

3

– manual valve closing:

Turn the valve knob counterclockwise to close

valve manually.

Please take care to drain the condensate regularly

9. Before starting the operation

Note:

Prior to installation, please observe the

air flow direction marked by arrows

• The filter-pressure reducer is equipped with a front

and a rear outlet for the manomenter. Close the

outlet not being used with the threaded plug

8

• Before pressurizing the system, fill the lubricator

with oil either directly by unscrewing the oil-cup

7

or through the oil filler plug

6

positioned on top of

the lubricator body.

Only use ISO and UNI FD oils.

10. Application

•

Air pressure adjusting:

By operating the pressure regulator

2

on top of

the filter-pressure reducer

1. Raise the pressure regulator knob

2

upwards

in order to permit rotation

2. Increase pressure: turn the knob clockwise

decrease pressure: turn the knob

counterclockwise

3. Once the desired pressure has been obtained,

push the knob downwards in order to lock it in

place.

4. With a final clockwise rotation the desired

pressure is built-up.

8. Technical data

Maintenance Unit

Filter-Pressure Reducer

9070-2

9070-3

9070-4

9070-5

9070-6

9070-7

Connecting thread

1

⁄

2

˝

3

⁄

8

˝

1

⁄

4

˝

1

⁄

2

˝

3

⁄

8

˝

1

⁄

4

˝

Flow rate at 6.3 bar

Nl/min

5000

5000

1800

5000

5000

1800

Working pressure max. bar

12

12

10

12

12

10

Pressure max.

bar

16

16

12

16

16

12

Pressure indication

bar

0,5 – 12

0,5 – 12

0,5 – 10

0,5 – 12

0,5 – 12

0,5 – 10

Permissible temperatur

range °C

-10 up to

+55

-10 up to

+55

-10 up to

+55

-10 up to

+55

-10 up to

+55

-10 up to

+55

Filter-Pressure Reducer

Capacity ml

50

50

30

50

50

30

Oil-cup

Capacity ml

170

170

40

–

–

–

Oil filter element

mm

10

10

10

10

10

10

Manometer connection

1

⁄

8

˝

1

⁄

8

˝

1

⁄

8

˝

1

⁄

8

˝

1

⁄

8

˝

1

⁄

8

˝