11

P3

…

/P3 Top Class

A2239-3.0 en/de/fr

HBM

4

Installation

The pressure transducer can be screwed in wherever required. If the

transducer is used to measure dynamic pressure characteristics in liquids, it

should be installed with the pressure connection pointing upward, so that it is

not possible for an air cushion to build up in the measurement tube.

The connecting pin with the M 12 x 1.5 and M 20 x 1.5 threaded connectors for

the P3/3000 bar type, corresponds to DIN 16288.

CAUTION:

When tightening, the wrench (27 a.f.) must only be put to the flat of the

mounting flange and not to the housing or to the cable entry. The

permissible tightening torque is 30 N

V

m.

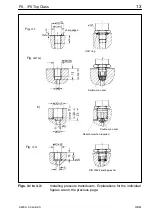

Pay particular attention to the sealing on the thread of the connecting pin. The

pressure medium and the respective conditions of installation for the individual

case will determine which type of sealing is suitable. Some of the sealing

options are shown below.

Fig. 4.1:

The USIT ring U 12.7 x 20 x 1.5 belongs to the accessories

supplied with the P3 transducer up to 500 bar full scale value. For a

perfect seal, the bearing surfaces must be mostly flat and without

marks. The pin hole must not have spot‐facing and should only be

slightly deburred, as the pressure of the measurement medium

pushes the lips of the seal against the transducer and the bearing

surface.

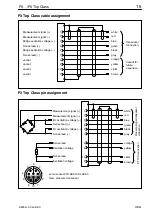

Fig. 4.2:

The transducers with the 500 to 3000 bar full scale value come

supplied with a double‐cone seal made of rustproof, acid‐proof

steel, material no. 1.4305. This makes a perfect seal, even at high

static and dynamic pressures.

a) P3/ 500 bar to P3/ 2000 bar

Connection hole and seal installation.

b) P3/ 3000 bar

Connection hole with relief bore and seal installation.

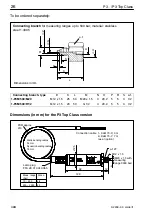

Fig. 4.3:

With this seal with sealing washers per DIN 16258, only washers

made of non‐metallic materials should be used. If relevant metallic

washers are used, the surface pressure required for a perfect seal