T12

64

A1979

−

10.0 en

HBM

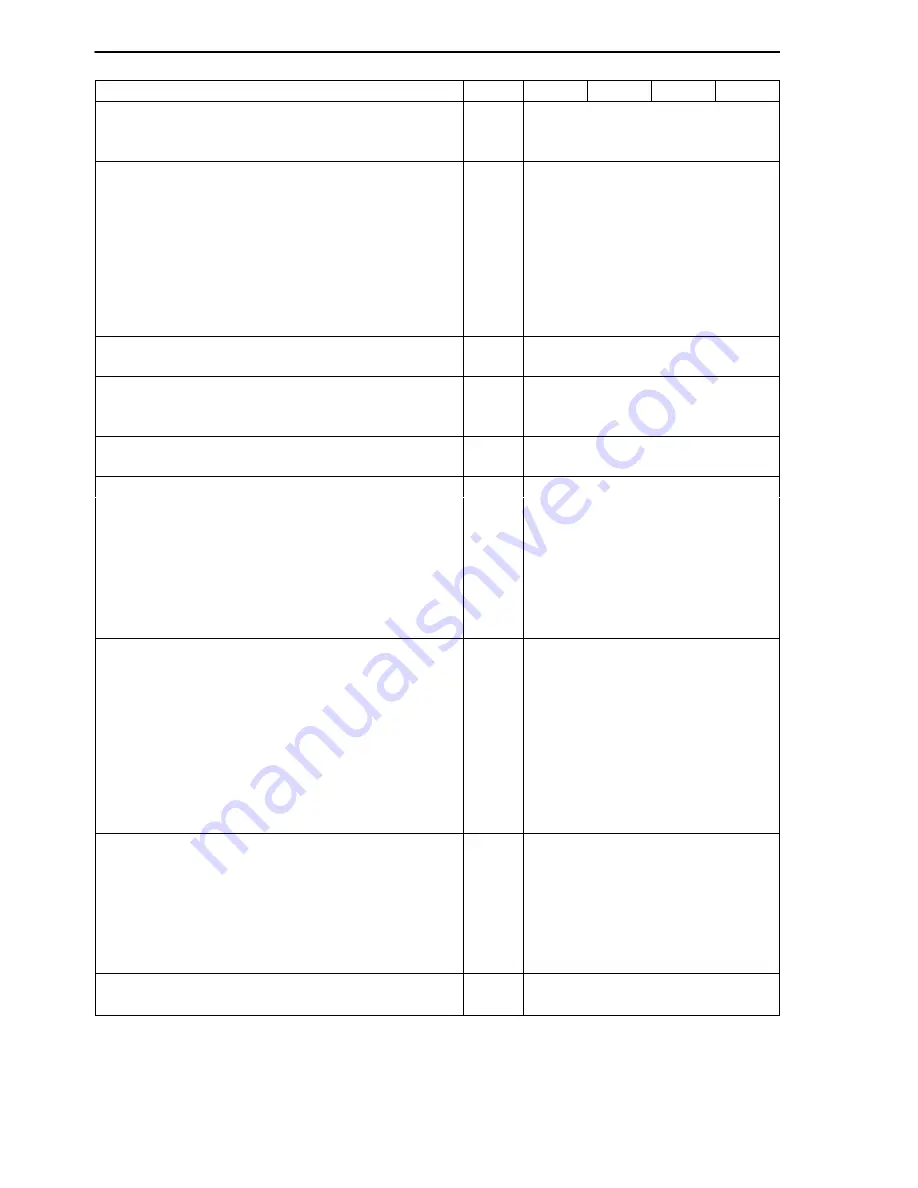

Nominal (rated) torque

M

nom

kN

m

2

3

5

10

Output signal at torque = zero

Frequency output 10 kHz/60 kHz

kHz

10/60

Voltage output

V

0

Nominal (rated) output signal

Frequency output

with positive nominal (rated) torque

10 kHz/60 kHz

kHz

15/90 (5 V symmetrical

2)

)

with negative nominal (rated) torque

10 kHz/60 kHz

kHz

5/30 (5 V symmetrical

2)

)

Voltage output

with positive nominal (rated) torque

V

+10

with negative nominal (rated) torque

V

−

10

Scaling range

Frequency output/voltage output

%

10 to 1000 (of

M

nom

)

Resolution

Frequency output 10 kHz/60 kHz

Hz

0.03/0.25

Voltage output

mV

0.33

Residual ripple

Voltage output

mV

3

Maximum modulation range

3)

Frequency output 10 kHz/60 kHz

kHz

4 to 16/24 0 96

Voltage output

V

−

10.2 to +10.2

Load resistance

Frequency output

k

2

Voltage output

k

10

Long-term drift over 48 h

Voltage output

mV

"

3

Measurement frequency range

Frequency output/voltage output

−

1 dB

Hz

0 to 4000

Frequency output/voltage output

−

3 dB

Hz

0 to 6000

Low-pass filter LP1

Hz

0.05 to 4000 (fourth-order Bessel,

−

1 dB); factory setting 1000 Hz

Low-pass filter LP2

Hz

0.05 to 100 (fourth-order Bessel,

−

1 dB); factory setting 1 Hz

Group delay (low-pass LP1: 4 kHz)

Frequency output 10 kHz/60 kHz

s

320/250

Voltage output

s

500

Energy supply

Nominal (rated) supply voltage (DC)

(separated extra-low voltage)

V

18 to 30

Current consumption in measuring mode

A

< 1 (typ. 0.5)

Current consumption in startup mode

A

< 4

Nominal (rated) power consumption

W

< 18

Maximum cable length

m

50

Shunt signal

50% of

M

nom

or 10% of

M

nom

Tolerance of the shunt signal, related to

M

nom

%

"

0.05

2)

RS

−

422 complementary signals, note termination resistance.

3)

Output signal range in which there is a repeatable correlation between torque and output signal.

Summary of Contents for T12

Page 1: ...A1979 10 0 en Digital Torque Transducer T12 Mounting Instructions ...

Page 2: ......

Page 89: ...89 T12 A1979 10 0 en HBM ...

Page 90: ...T12 90 A1979 10 0 en HBM ...

Page 91: ......