20

HBM T40MS 2020 en (11.03.2020) HBM: public

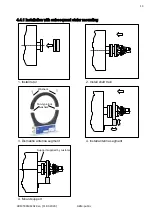

4.7 Speed measuring system, reference pulse

The optional rotational speed measuring system (also with the additional reference

signal and zero index option) is integrated into the transducer at the factory,

so no installation is required.

Fig. 4.7:

Torque transducer with rotational speed measurement and reference signal

Rotational speed measuring system sensor head alignment

If the stator is accurately aligned for torque measurement, the rotational speed

measuring system and the sensor for the reference signal (zero index) are also

correctly aligned. So the two Allen screws on the sensor head (Fig. 5.10) must

not be loosened.

Important

You must not change the position of the sensor head.

Important

This is a magnetic rotational speed measuring system.

In applications where magnetic strengths are expected to be high (such as an

eddycurrent brake), suitable action must be taken to ensure that the max.

magnetic field strength stated in the specification is not exceeded.

Magnetic ring for rotational speed

measurement

Sensor head for the reference signal

Sensor head for measuring

rotational speed

Summary of Contents for T40MS

Page 1: ...HBM T40MS 2020 en 11 03 2020 HBM public Mounting Instructions English T40MS...

Page 2: ...HBM T40MS 2020 en 11 03 2020 HBM public...

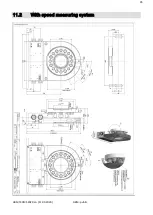

Page 38: ...34 HBM T40MS 2020 en 11 03 2020 HBM public 11 Dimensions 11 1 Without speed measuring system...

Page 39: ...35 HBM T40MS 2020 en 11 03 2020 HBM public 11 2 With speed measuring system...