10

U3

HBM 11.12.2000

5

Mechanical installation

5.1

Important measures for installation

•

Treat the transducer gently.

•

Do not overload the transducer.

•

Either during installation or immediately afterwards, the transducer should

be bridged by a 50mm

2

stranded copper wire (highly flexible signal ground

cable EEK from the HBM line). The cable is attached by screws both above

and below the transducer. This prevents welding current flowing over the

transducer and welding the force introduction point.

WARNING

If there is a risk of breakage through overload on the transducer

and thus a risk to persons, additional safety measures are to be

taken.

5.2

General installation guidelines

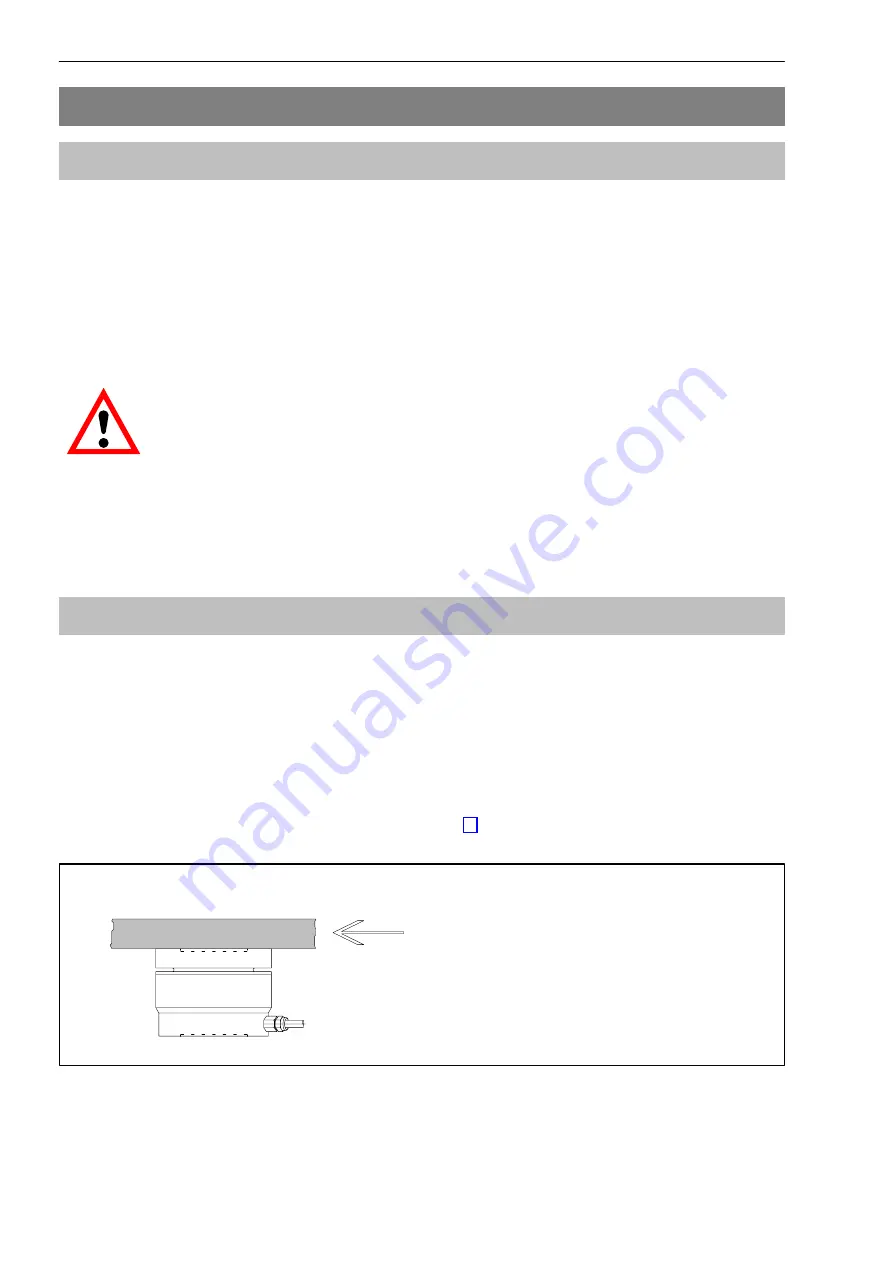

The direction of measurement in which the forces work should be as much

towards the transducer as possible. Torsion and bending moments, eccentric

loading and transverse forces may result in measurement errors and if the

limit values are exceeded, could destroy the transducer.

The transducer can take up 100% (80% at 50kN, 50% at 100kN) of its

nominal force as transverse force by reference to a force introduction point on

the force–introduction surface (see diagram Fig. 5.1), without losing its

mechanical competence.

Transverse force

Fig. 5.1

Transverse force introduction

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com