4 Planning and installation – Scope of delivery

38

The return temperature control consists of a 3-way mixing valve with

a 230 V servo drive (running time 120-240 s) and a circulation pump

from energy efficiency class A. We recommend for the

•

HDG Compact 25/35/45/50/65:

Wilo 30/1-7.5, 3-way mixing valve DN 32

•

HDG Compact 80:

Wilo 30/1-8, 3-way mixing valve DN 40

(or comparable)

The hydraulic system must be installed in accordance with specific

technical principles of the heating construction industry. Take into

account the isolation valves required for maintenance work and re-

pairs.

The return temperature control must be installed according to the

specifications of HDG Bavaria.

4.4 Scope of delivery

Included in the scope of delivery:

•

HDG Compact 25 - 80 boiler

•

Cladding

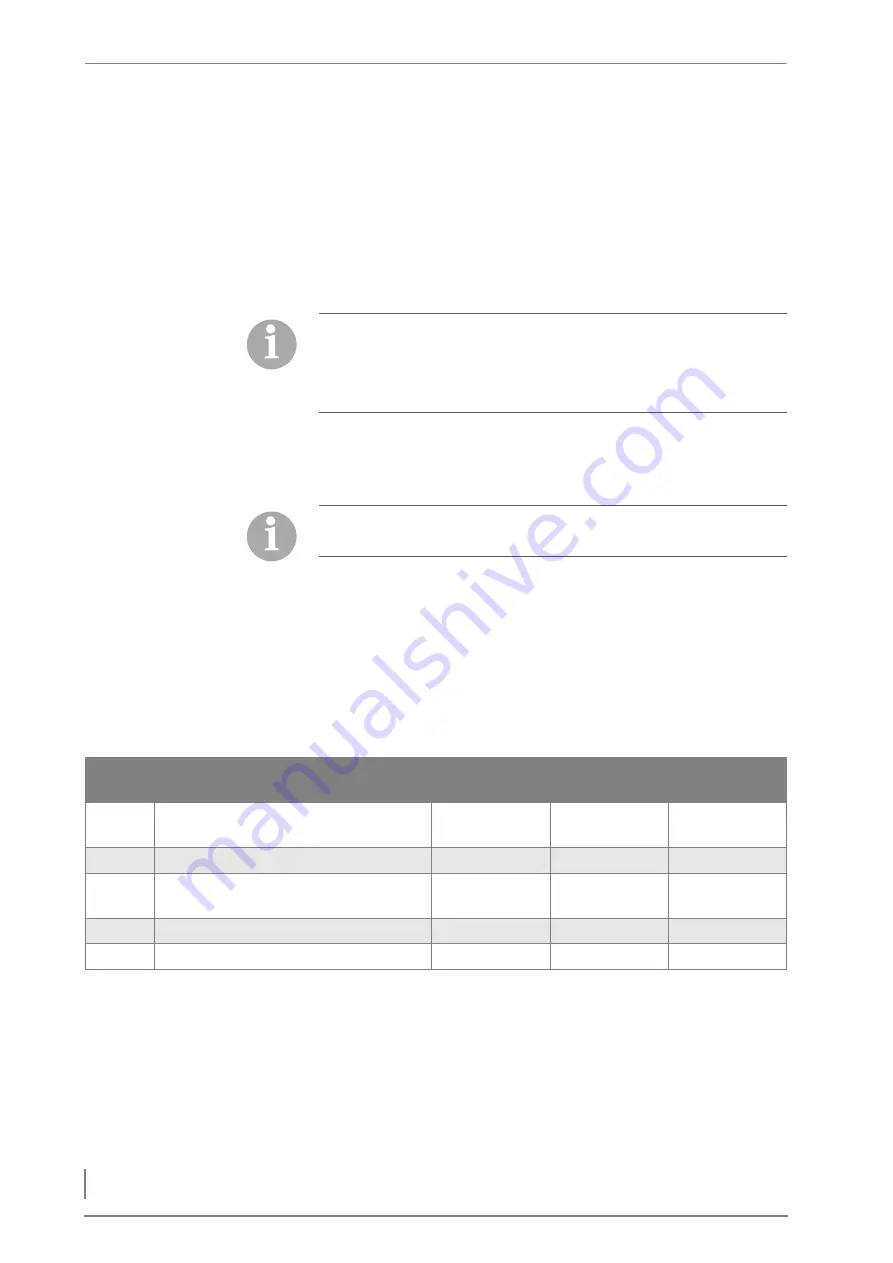

x = included, o = optional

•

Feeding system (customer-specific)

•

Delivery system (customer-specific)

•

Cleaning tools

•

Operating documentation

Upon delivery, check that the scope of delivery matches the informa-

tion on the delivery note.

The pipe dimensions must be adapted to meet the requirements at

the site. Take the water-side connections of the boiler for the supply

and return into account.

✎

See chapter “3 Mode of operation”, section “3.3 Technical data”.

The return temperature control is not designed for the use of a

gravity brake and this should therefore not be installed.

Packet

Change

HDG Compact

25/35

HDG Compact

45/50/65

HDG Compact

80

1A

Supporting structure and assembly

material

x

x

x

1B

Back side

in packet 1A

x

x

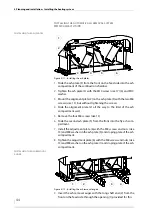

2

Feeding system side and flue gas pipe

side

x

x

x

3

Cladding for pellet vacuum container

o

o

o

4

Front and top

x

x

x

Table 4/4 - Dimensions on back side, HDG Compact 25 - 80 (mm)