7 Cleaning and maintaining the heating system – Procedure

148

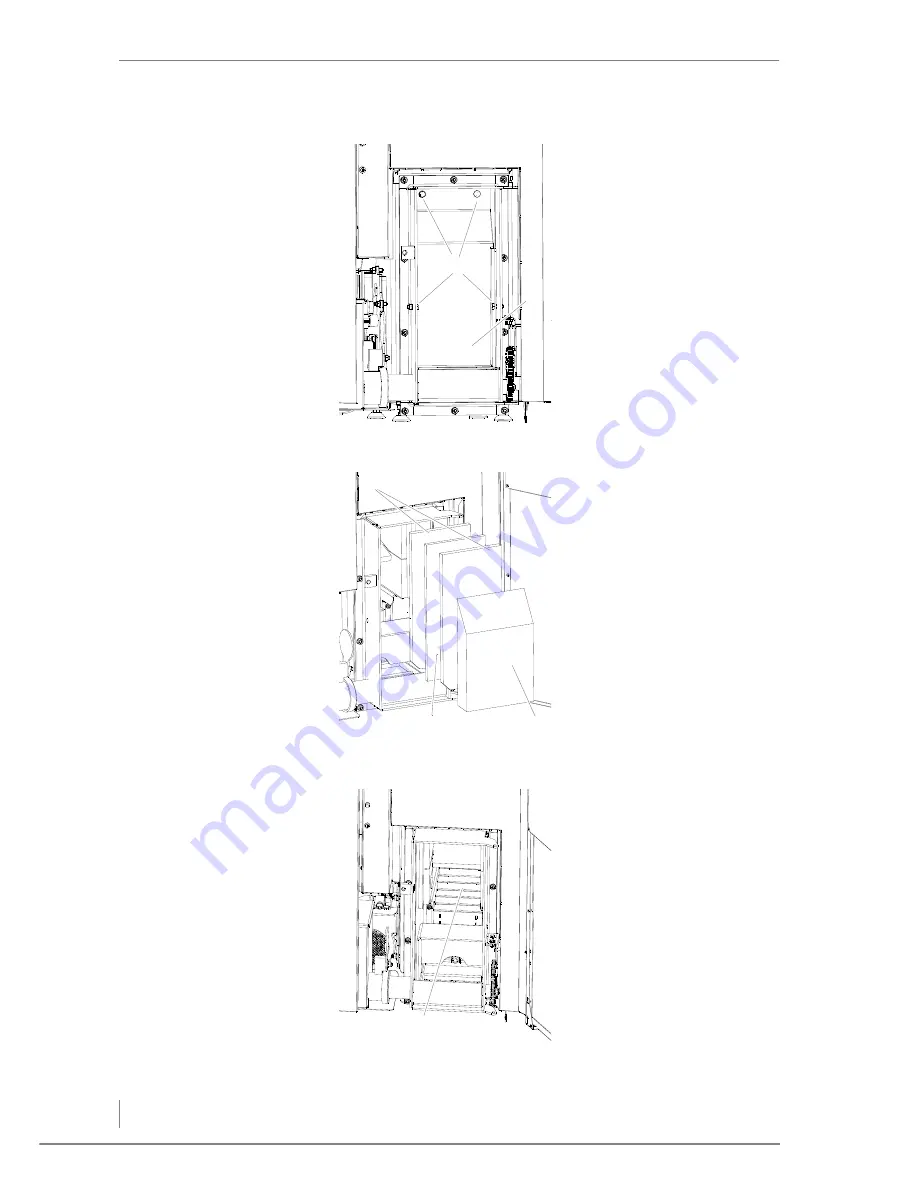

8.

Release and remove the M8

screws (2) using a 13 mm

spanner.

9.

Remove the deflector

plate (1).

Figure 7/5 - Removing the deflector plate

2

1

10.

Remove the insulating

piece (2).

11.

Remove the two stones (1)

lying behind it with the

insulation in between (3).

Figure 7/6 - Removing stones and insulation in between

1

2

3

12.

Check the stepped grate (1)

for ash and dirt.

13.

If necessary, clean the

stepped grate (1) with a

vacuum cleaner.

Figure 7/7 - Checking and cleaning the stepped grate

1

Summary of Contents for Pelletmaster 15

Page 1: ...hdg bavaria com HDG Pelletmaster 15 25 Operation Manual V 03 08 2008 ...

Page 2: ......

Page 170: ...170 HDG Pelletmaster 15 25 V 03 en HDG Bavaria GmbH 08 2008 ...

Page 171: ......