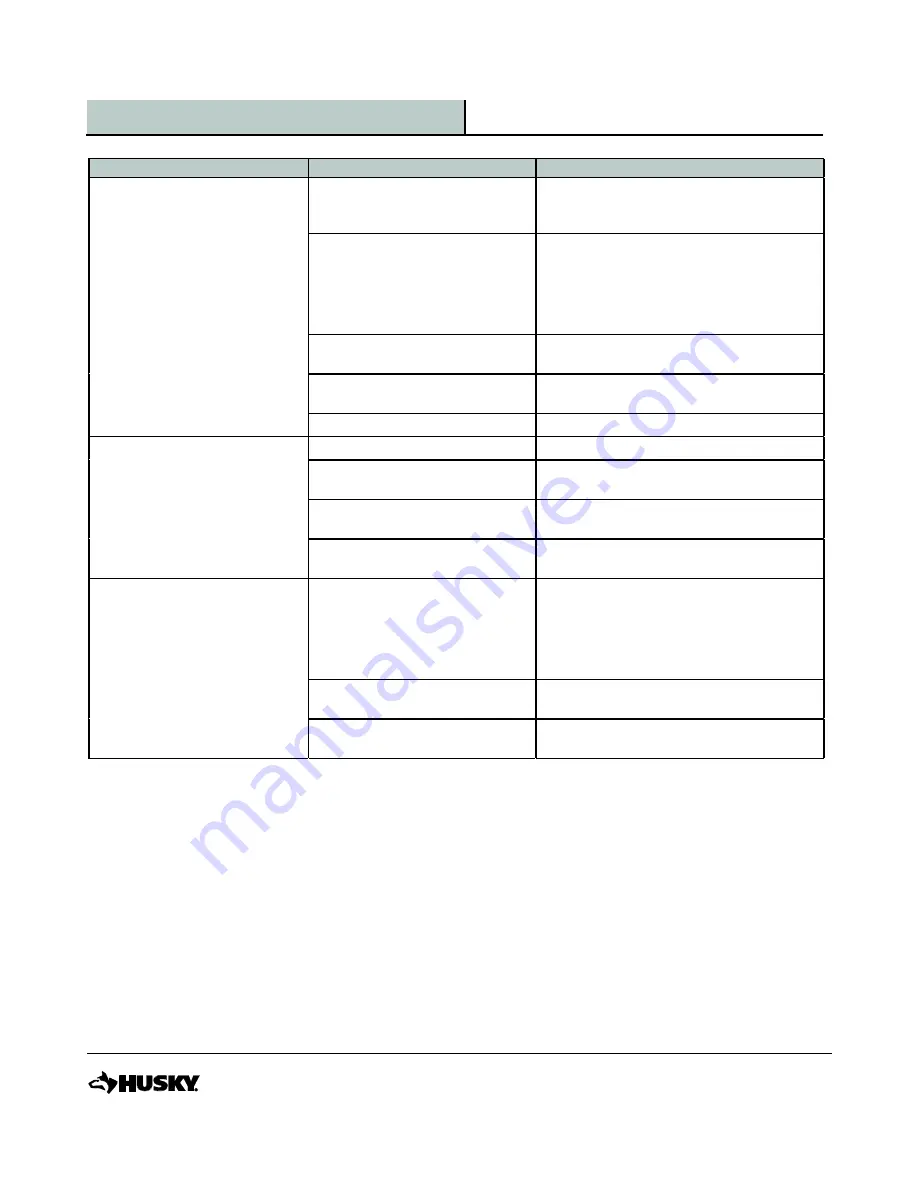

Troubleshooting

Problem

Compressor does not run.

Motor hums but does not run or

runs slowly.

Fuses blow or circuit breaker trips

repeatedly.

Possible Cause

□ Tank has insufficient pressure.

□ No electrical power.

□ Blown stop/house fuse.

□ Tripped shop/home breaker.

□ Thermal overload is open.

□ Loss of power or overheating.

□ Pressure switch is bad.

□ Low voltage.

□ Wrong gauge wire or length

of extension cord.

□ Shorted or open motor

winding.

□ Defective check valve or

unloader.

□ Incorrect fuse size, circuit

overload.

□ Wrong gauge wire or length

of extension cord.

□ Defective check valve or

unloader.

Solution

□ When the tank pressure drops, the

compressor will turn on to cut-in

pressure.

□ Ensure the compressor is plugged into a

good outlet.

□ Replace the shop/house fuse.

□ Reset the shop/home breaker and

determine the underlying cause.

□ Unplug the compressor and wait for it to

cool. Then try using again.

□ If using an extension cord, check for

proper use.

□ Replace the pressure switch.

□ Check voltage with a voltmeter.

□ Verify proper gauge wire and cord

length are used.

□ Bring the compressor to a service

center.

□ Bring the compressor to a service

center.

□ Verify proper fuse size is being used.

□ Use time-delay fuses.

□ Disconnect other electrical appliances

from the circuit or operate compressor

on its own branch circuit.

□ Verify proper gauge wire and cord

length are used.

□ Bring the compressor to a service

center.

8