Doc No. XG-0042 Rev No. 042808

3

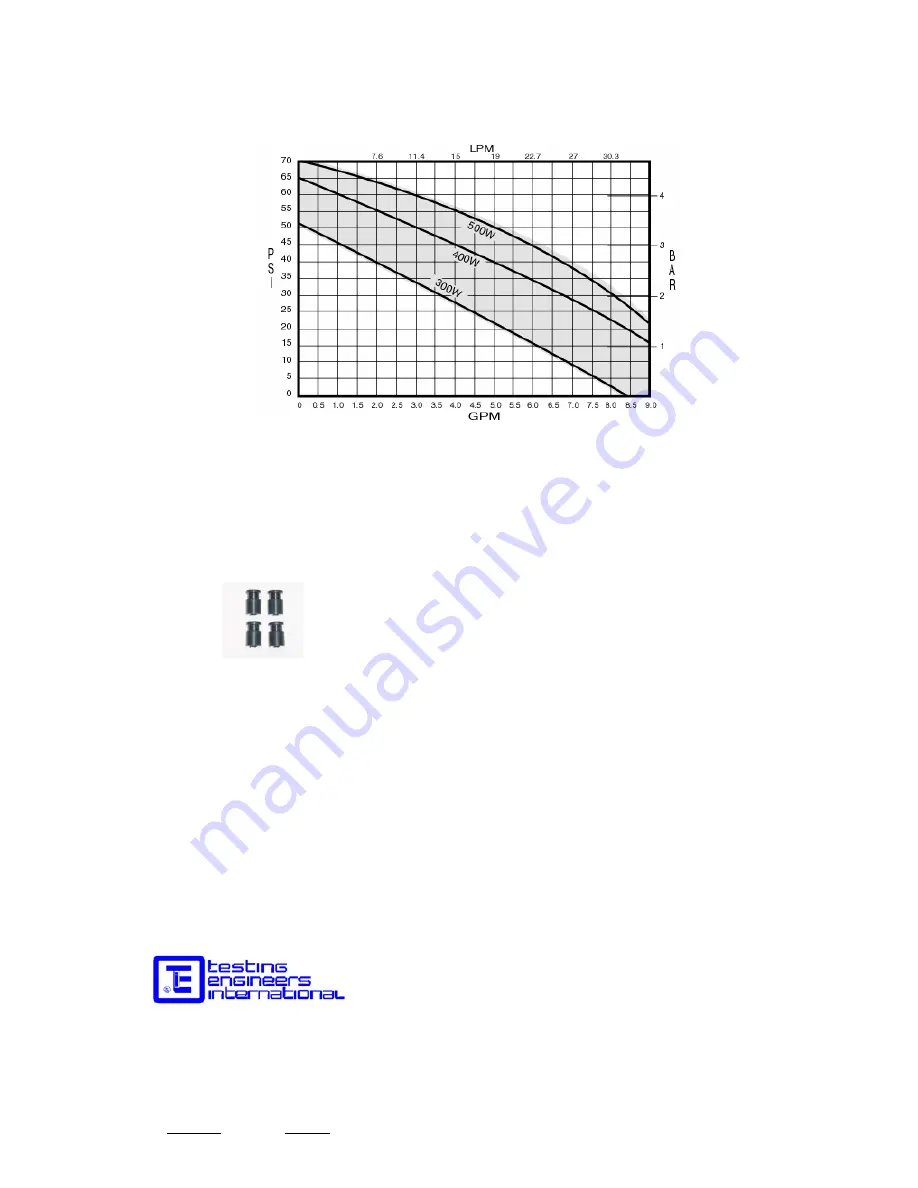

Performance Curves:

What’s in the Box:

Following is a list of components included in every X-Caliber box.

1

XR-124 or XRS-124 X-Caliber 12/24VDC Water Pump

1

X-Caliber Installation and Operation Manual

4

Rubber Vibration Isolation Mounts

Fluid Requirements:

There are two different versions of the X-Caliber water pump.

The XR-124 is designed for freshwater applications. It cannot be operated on saltwater.

The XRS-124 is a more corrosion resistant version of the pump using all 316 Stainless Steel wetted components

and is designed for salt or fresh water applications. Both the XR-124 and the XRS-124 pumps are suitable for

rainwater and drinking water applications.

Consult the technical label on the top of the pump to ensure the right pump has been provided for the application.

The X-Caliber is not intended for pumping fuel or any other flammable fluids.

Listing/Certifications:

The X-Caliber has been tested and certified to surpass all requirements of Underwriters Laboratories

UL 778 specifications for Motor Operated Pumps, UL 1113 specifications for Electrically Operated

Pumps for Nonflammable Liquids, Marine and is approved for drinking water use.

СЄ

LISTING # 01C01

Summary of Contents for X-CALIBER XR-124

Page 1: ...Doc No XG 0042 Rev No 042808...

Page 10: ...Doc No XG 0042 Rev No 042808 9 How to change pump settings...

Page 16: ......