Receptacle top surface

flush with floor.

HealthCraft Products Inc., Toll Free 888-619-9992.

2790 Fenton Road, Ottawa, Ontario, Canada, K1T 3T7.

DC109 Rev B

Page 2 of 4

Specifications subject to change without notice.

FLOOR RECEPTACLE INSTALLATION

Read these instructions in their entirety prior to

commencing installation or use of the SuperPole™ FRS .

1. Using suggestions on page 1, determine a proposed

location for installation of the floor receptacle(s).

2. Check that the concrete floor is in good condition, and

that the depth of the slab is at least six inches prior to

drilling.

IMPORTANT

- Determine if there are any

conduits, wires, pipes or such within the floor to be

avoided during drilling, or a potential for the bottom of the

hole to fall through.

3. Select a locally available anchoring cement or

embedment grout to be used for the installation. It should

have a hardened bond and pullout strength of at least

2000 psi, compatibility with your floor cleaning chemicals,

and a pourable semi-liquid like consistency. (Suggestions

for this grout include HILTI HIT-HY150, from HILTI or

Anchorite Embedment Grout from C.C. Chemicals

Canada). Your selected grout should be confirmed to be

in accordance with any local codes in your area for safety,

disposal, and germ prevention.

4. Prepare to drill the hole for the receptacle. It is

recommended to create the hole with a 2" to 2-1/4"

diameter diamond type coring hole saw. The two inch size

results in the cleanest appearance of the hole with a

minimal appearance of grout around the receptacle, but

requires a flowable grout to fill into the small area around

the receptacle.

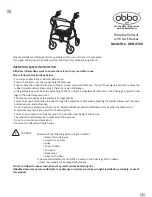

5. Referring to

Figures 1, 2 & 3

, the hole should be drilled

to 4-1/4" to 4-1/2" deep, and aligned as true vertical.

Follow the grout manufacturers’ guidelines for hole

preparation such as cleaning and roughening the hole

prior to using grout.

6. Referring to

Figure 2

, prior to mixing the grout, make a

test and lower the receptacle into the hole. Test that the

top of the receptacle does not sit above floor level. You

may choose to use thin metal pieces such as large

washers to place under the receptacle to shim it such that

the top of the receptacle is flush with the floor surface.

7. Once the hole and receptacle have been prepared for

installation, prepare the grout following manufacturer’s

directions. Referring to

Figure 3

, place/pour an amount of

the grout in the bottom of the drilled hole. You may also

apply some of the grout onto the sides of the receptacle to

pre-coat it for better adhesion.

Figure 3: Clean Hole & Add Anchoring Grout.

Figure 1: Locate & Drill Hole for Receptacle.

Figure 2: Test Hole Diameter and Depth.

Spacer Shims (if needed).

Qualified anchoring cement

or embedment grout.

Starting amount of anchoring

cement or embedment grout.

Approx. Depth

3"(2"Hole)

2"(2-1/4"Hole)

FRS Floor Receptacle.

Spacer Shims (if needed) as appropriate to bring

top surface of receptacle flush with floor surface.

2" to 2-1/4"

Concrete Floor /

SubFloor.

Correctly located

hole for receptacle.

Concrete Hole Saw

(Use 2" dia. for

cleanest appearance).

• Check for in-floor items such as conduit & pipes.

• Check for dangers below hole, such as wires,

fall through potential.

Hole Depth

4-1/4" to

4-1/2"

6" MIN

Floor

Depth

Clean & prepare hole

per grout manufacturer

instructions.