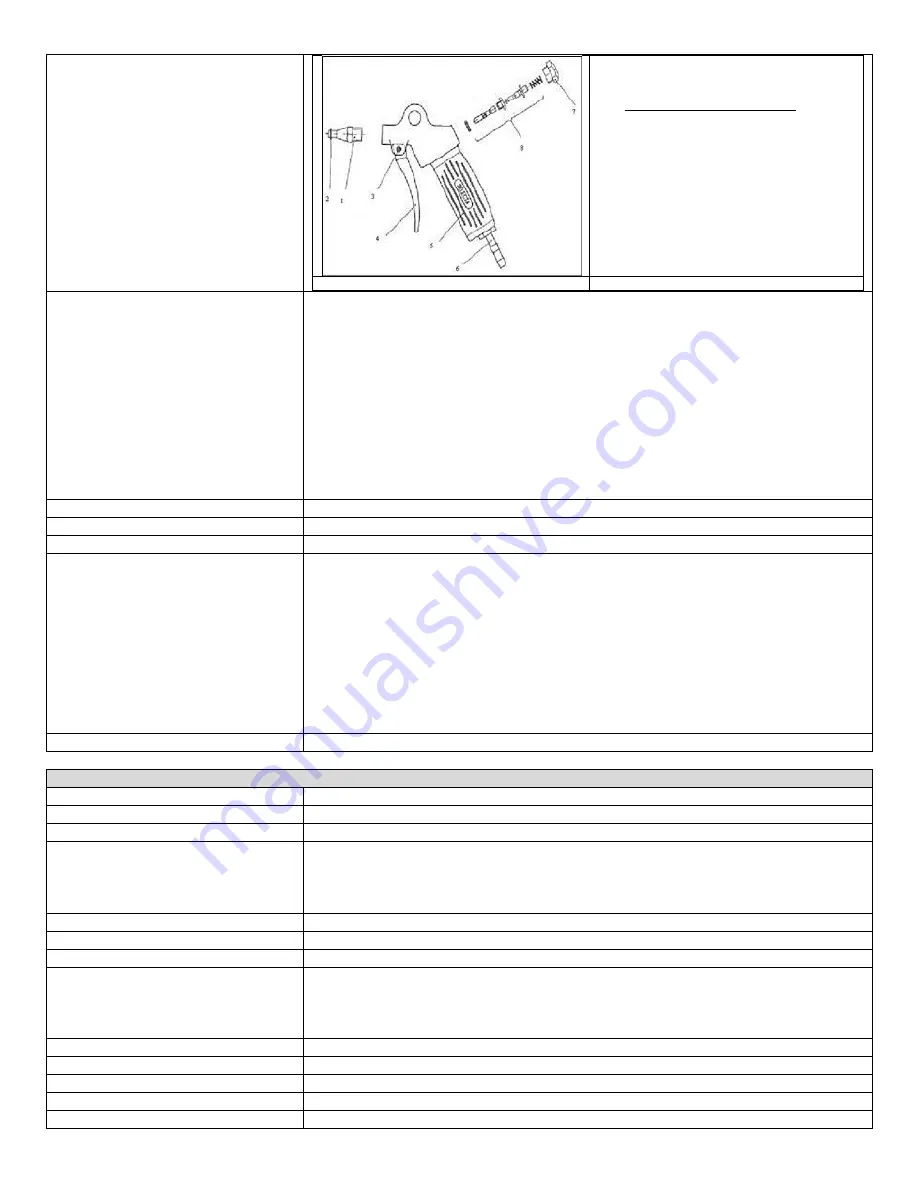

Key to Spray Gun Components

1.

Gun Rinser Tip Holder complete kit

2.

“O” Ring black 3mm x 1mm

3.

Spiral Tension Pin

4.

Trigger Handle

5.

Grip for Spray Gun

6.

Hose Connector

7.

Gun Cap

8.

Flow Control Kit

Figure 5: Diagram Spray Gun Contruction

Steps for Use of Product

1.

Prior to operation, the user must make sure that the attachments are correctly seated on

the safety conell by firmly pushing them onto the spray gun rinser tip. Make sure the

valve is open that is attached to the hose.

2.

When in operation, the Spray Gun must not be pointed at parts or orifices of the body

because the compressed water or air jet may be harmful.

3.

Depending on the field of application, suitable safety measures must be taken to

protect the user from splashes of contaminated water (protective goggles, protective

mask, etc.).

4.

If required, the maximum water or air pressure value can be set by using the small

threaded nut located behind the trigger handle.

5.

The flow is controlled by pulling the trigger - up to the maximum set point fixed by the

threaded nut.

Interpretation of Results

Contraindications of Test Results

Documentation

Special Warnings and Cautions

If tubing other than that supplied by Healthmark is used, facility should independently

verify the safe and effective performance of that tubing. The liability for damage or

industry is the responsibility of the facility.

Warranty claims will only be honored for components purchased from Healthmark.

Maximum water or air pressure to use is 6 bar (86 psi).

The Spray Gun is not a medical product and is therefore not to be used as part of

medical treatments.

When in operation, the Spray Gun must not be pointed at parts or orifices of the body

because the compressed water or air jet may be harmful.

Be sure to wear proper PPE according to facility and industry guidelines.

Disposal

Reprocessing Instructions

Point of use:

Preparation for decontamination:

Disassembly Instructions:

Cleaning – Manual:

The Spray Gun with the blue silicone grip may only be cleaned with warm water and a

mild detergent.

It is not necessary to carry out water quality tests, but the user should not operate the

Spray Gun with de-mineralized water since it causes corrosion.

Cleaning – Automated:

Disinfection:

Drying:

Maintenance, inspection, and testing:

It is recommended to decalcify the Spray Gun approximately every four weeks. The

gun should be disassembled and the inner parts placed in a decalcifying agent. This is

beneficial for the service life and reliability of the spray gun.

Replacement parts and instructions for repair are available from Healthmark.

Reassembly Instructions:

Packaging:

Sterilization:

Storage:

Additional Information: