The Cleaning Spray Gun features a new type of

internal flow control

mechanism. It permits the

smooth and simple adjust-

ment of the water or air

flow across the entire

range of the trigger move-

ment. If required, the

maximum water or air

pressure value can be set

by using the small threaded

nut (Fig. 2) located behind the trigger handle.

The flow is determined by pulling up to the set

maximum point threaded. Prior to operation, the

user must

make sure that

the attach-

ments are cor-

rectly seated

on the safety

conell by sim-

ply pushing

them onto the

spray gun rin-

ser tip (Fig.3 &

3A). Even high pressure cannot disconnect them.

When in operation, the Spray Gun must not be

pointed at parts or orifices of the body because the

compressed water or air jet may be harmful. De-

pending on the field of application, suitable safety

measures must be taken to protect the user from

splashes of contaminated water (protective goggles,

protective mask, etc.). If other tubings than those

supplied by Healthmark are to be used, it must be

ensured that they have been approved by a testing

lab. Warranty claims will only be honored for com-

ponents purchased from Healthmark.

Specifications:

max. water or air pressure 6 bar (86

psi)

Safety Instructions:

The Spray Gun is not a medi-

cal product and is therefore not to be used as part of

medical treatments.

I N S T R U C T I O N O F U S E

The Spray Gun with the blue silicone grip may

only be cleaned with warm water and a mild de-

tergent. It is not necessary to carry out water qual-

ity tests, but the user should not operate the Spray

Gun with de-mineralized water since it causes

corrosion. It is recommended to decalcify the

Spray Gun approximately every four weeks. The

gun should be disassembled and the inner parts

(Fig. 5 #8 (80-00-44) ) placed in a decalcifying

agent. This is beneficial for the service life and

reliability of the spray gun.

M A I N T E N A N C E

Fig. 2

Fig. 3

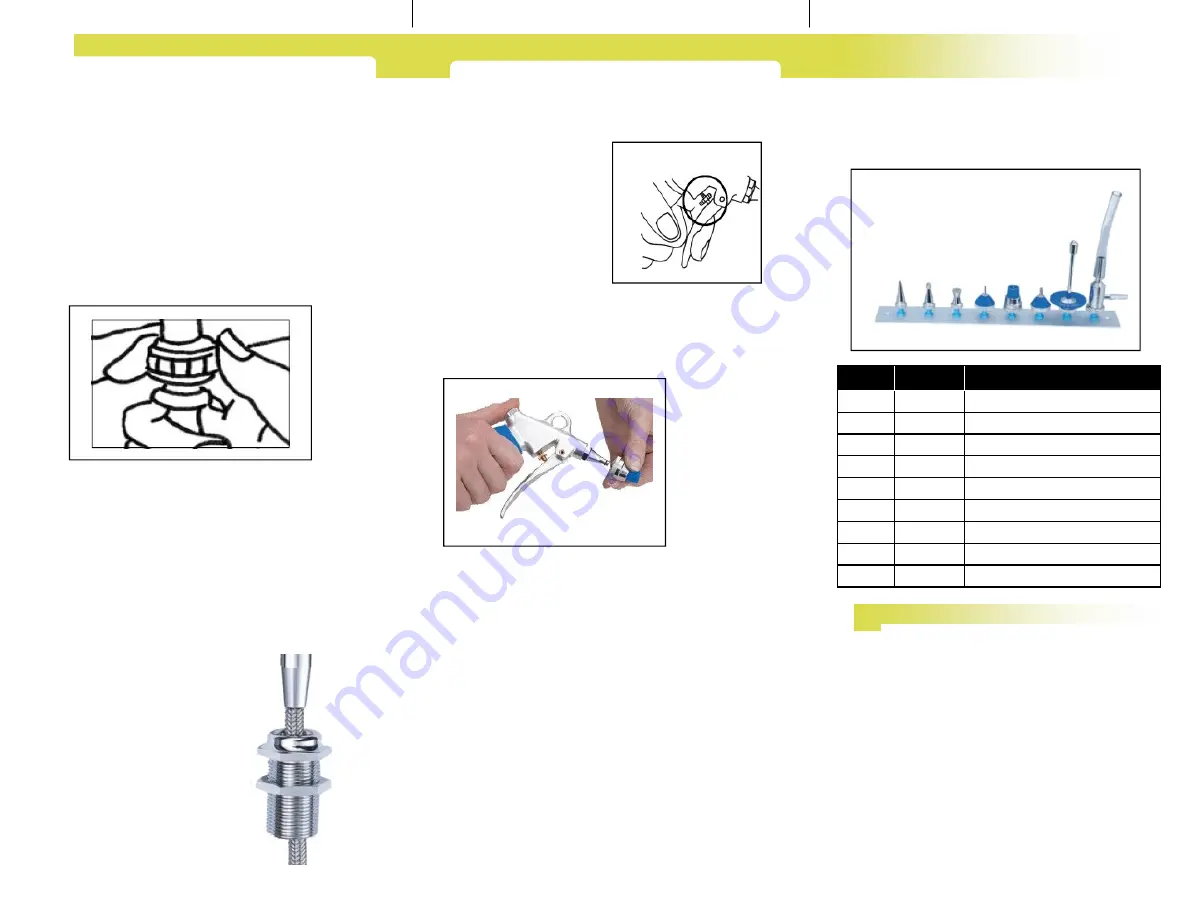

No.

Part No.

Description

1

80-01-05

Universal tip

2

80-01-06

For drainage tube

3

80-01-08

Spray jet for rinsing out glassware, etc.

4

80-10-40

For syringes and cannulae with cone

5

80-10-41

For pipettes

6

80-10-42

For syringes and cannulae with Luer cone

7

80-10-43

For bottles and Erlenmeyer flasks

8

80-10-44

Water jet for suction pump cannisters

1-8

80-01-38

Complete set with rack

P I C K T H E C O R R E C T

T I P A T T A C H M E N T S

Congratulations on the purchase of your new

Cleaning Spray Gun! You are moments away

from using this outstanding new tool. It is easy

to install for either water or air. It is best in-

stalled by a licensed plumber. Please contact

Facilities and/or Engineering concerning any

special requirements.

Connection Requirements:

Water Connection:

Plumbing threaded tap or valve - 3/8”, 1/2” or

3/4” (standard gun kit includes 3/4” female

connection).

Air Connection:

If operated with compressed air, the tubing

must be

connected to the air supply by suitable con-

nector

(cannot be supplied by Healthmark).

Counter Top Rosette

If you plan to connect your

gun to water or air below the

counter we recommend a

rosette be installed. It will

minimize potential friction

damage to the hose. A 1 3/8”

diameter hole will need to be

drilled in the counter or sink

top to accommodate the ro-

sette.

I N S T A L L A T I O N

Fig. 1

Fig. 3A

1

2

3

4

5

6

7

8

1