Hearth & Home Technologies • Grand Oak Gas Log Sets • 4004-320 2/2011

5

Table 1 for Factory Built Fireplaces

Free Opening Area (in square inches) of

Chimney Damper for Venting combustion

Chimney Ht.

(Feet)*

ODGO 324

LP Gas

ODGO 324

Natural Gas

10

35.3

not approved

15

26.4

38.5

20

22.1

31.2

25

18.1

27.3

30

17.3

24.6

35

15.9

22.1

Table 2 for Masonary Built

Fireplaces

Free Opening Area (in square inches) of

Chimney Damper for Venting combustion

Chimney Ht.

(Feet)*

ODGO 324

LP Gas

ODGO3 24

Natural Gas

6

49.2

64

8

45.5

59.7

10

41.7

54.3

15

37.7

48.8

20

34.3

44.4

30

31.2

40.3

Table 3 for Minimum Fireplace Dimensions

Log Set

Front

Opening

Depth

Height

Rear

Width

Natural

BTU

Propane

BTU

ODGO324

34 in.

23 in.

22 in.

22 in.

88,000

80,000

G. Inspect the Appliance and Components

• Remove the contents from the carton labeled “Burner”.

Attached to the burner are tags identifying the manufacturer

name, serial number, model number (including gas log

size), BTU ratings, gas type, etc.

• Review the attached tags before proceeding. Ensure

that all minimum fireplace dimension requirements are

achieved using Table 3 . See Figure 1. Ensure the gas

type provided in the fireplace coincide with the gas type

marked on the tag.

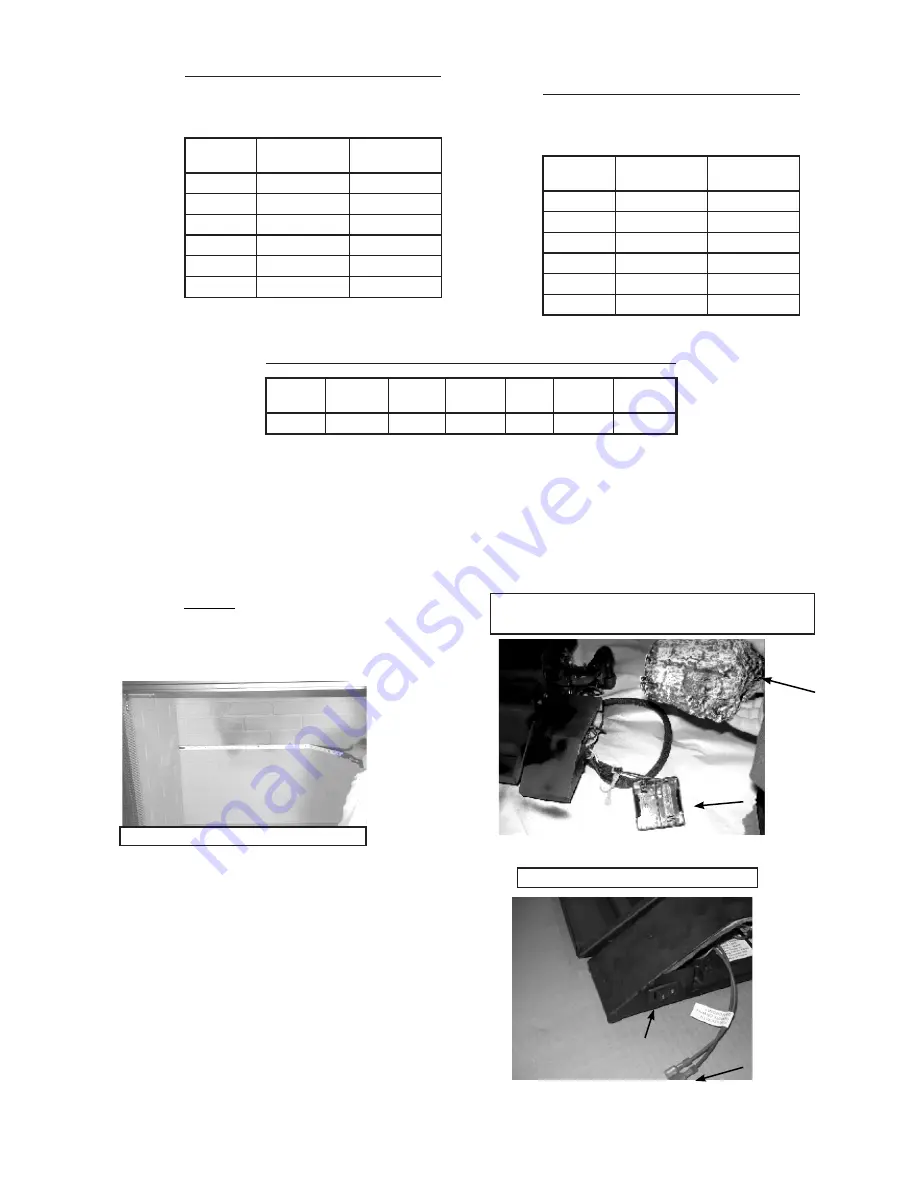

Figure 1

Measure Firebox

• The burner is assembled with the controls installed at the

factory and is designed to connect one end of the 3/8 in.

supply line before placing inside the fireplace. Ensure the

connection is tightened using a 3/4 in. wrench.

• Place the burner towards the rear and center of the

fireplace and connect to the gas line. Follow instructions

in “F. Gas Pressure” to check for gas leaks.

• IPI models include a battery box which holds 2 “D” size

batterys. The battery box should be placed in the right

front corner of your fireplace and covered with the log

cover as shown in Figure 3.

• An On/Off switch is provided as part of the assembly. It

is located on the front right side of the burner assembly

as shown in Figure 3A.

• Optional remote control system can be incorporated

with this system by connecting the remote system to the

connection wires shown in Figure 3A.

Figure 3

Battery Box and Cover (for IPI units only)

Battery Box Cover

Battery Box

Figure 3A Control Box for IPI

Optional Remote

Connection

On/Off Switch