1

Heat & Glo • PVK-80 Power Vent Instructions • 655-900 Rev. O • 12/09

PVK-80 Power Vent

- Installation Instructions -

PVK-80 POWERVENT

6.

CLEARANCES BETWEEN THE VENT PIPE AND

COMBUSTIBLE MATERIALS MUST BE MAIN-

TAINED AT 3 INCH TOP, 1- NCH SIDES, AND 1

INCH BOTTOM.

7.

CAUTION:

Failure to install, operate, and main-

tain the power venting system in accordance with

manufacturer's instructions will result in conditions

which may produce bodily injury and/or property

damage.

INSTALLATION OF PVK-80 POWER VENT

Note:

Some fi replace models may have unique venting

and/or wiring requirements when used with the PVK-80. In

those cases, PVK-80 instructions those manuals supersede

these instructions.

1. Location of venting system terminations must be made

in accordance with national, provincial, and/or local

codes. The minimum clearance requirements must be

followed on models using the PVK-80 Power Vent.

A. The exit termination of mechanical draft systems

shall not be less than 7 feet above grade when

located adjacent to public walkways and at least

10 feet from lot line or adjacent buildings.

B. A mechanical drafting venting system shall termi-

nate at least 3 feet above any forced air inlet located

within 10 feet.

C. The venting system of direct vent appliances shall

terminate at least 12 inches below, 12 inches

horizontally from, or 12 inches above any building

opening through which fl ue gases could enter.

D. The vent termination point shall not be installed

closer than 2 feet from an inside corner of an L-

shaped structure.

E. The vent termination should not be mounted directly

above or within 3 feet horizontally from an oil tank

vent or gas meter.

F. The bottom of the vent termination shall be located

at least 2 feet above the fi nished graded and 2 feet

above any combustible projection.

Note:

The PVK-80 Power Vent must terminate in a

HORIZONTAL

position. See Figure 1.

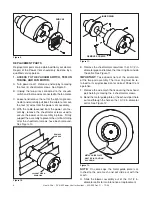

2. Install vent system components per planned vent

run. Route the vent pipe from the fi replace to the

Power Vent using the minimum number of elbows

possible. Refer to Tables 2 and 3 for vent specifi ca-

tions per size of vent pipe used.

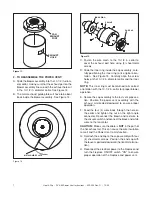

Note:

Most direct vent fi replaces can use either 4 in./ 6-5/8 in.

or 5 in. / 8 in. direct vent pipe components when using the PVK-

80 and conforming to the parameters in Tables 2 and 3.

IMPORTANT:

Failure to read and follow these instruc-

tions may create a possible hazard and will void the

fi replace warranty.

THESE INSTRUCTIONS MUST REMAIN WITH THE

EQUIPMENT.

INTRODUCTION

Models PVK-80 Power Vent can be used on direct

vent gas fi replaces manufactured by Hearth & Home

Technologies.

Any gas fi replace fi tted with the PVK-80 Power Vent

must utilize DSI (direct spark ignition) or IPI (intermit-

tent pilot ignition) fi replace gas controls. Fireplaces

equipped with millivolt type gas controls

CANNOT

use

this Power Vent.

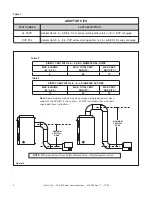

Tables 2 and 3 list the type and size of vent pipe,

maximum number of 90° elbows, maximum total vent

pipe run, and maximum vertical drop allowed when

using this Power Vent.

The PVK-80 Power Vent operates on 120VAC, 60Hz

electrical service which is supplied at the fi replace

junction box.

INSTALLATION PRECAUTIONS

1. This device must be installed by a qualifi ed installer

in accordance with these instructions.

2. Safety inspection of the venting system should

be performed before and after installation of this

power vent. Consult local code offi cials and follow

applicable installation codes.

3.

DO NOT INSTALL DAMAGED EQUIPMENT OR

VENT COMPONENTS.

4. Disconnect electrical power supply before making

wiring connections.

5.

VENTING OF MORE THAN ONE APPLIANCE IN

A COMMON VENT SYSTEM IS PROHIBITED.