53

Hearth & Home Technologies • B41L-AU Installation Manual • 2570-980 Rev. C • 7/20

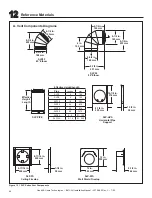

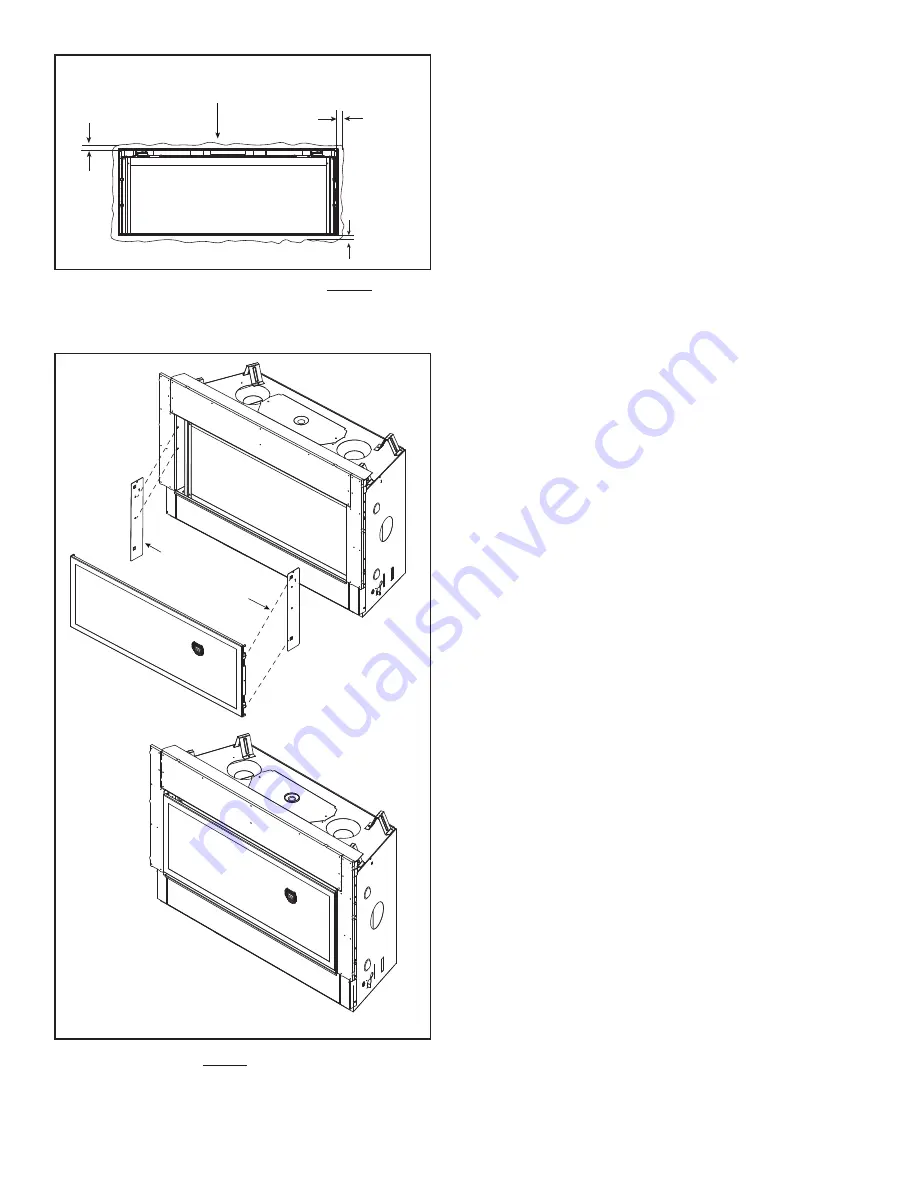

Figure 10.15 CFTF Front Without Outer Decorative Barrier Front

Trim

CFTF Decorative Barrier Front

Non-Combustible Finish Material 1-6 in. (25-152 mm) Thick

0 IN. / mm

0 IN. / mm

(CFTF)

0 IN. / mm

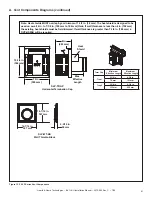

Figure 10.14 Clearances to Appliance Opening Without Outer

Decorative Barrier Front Trim

(BOTH SIDES)

(BOTH SIDES)

FACE OF NON-COMBUSTIBLE BOARD

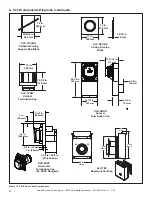

AUXILIAR

Y HANGING

BRACKETS