Heatmaster/American Gas Log, LLC • 16-1012 • Rev D. 03/2018

5

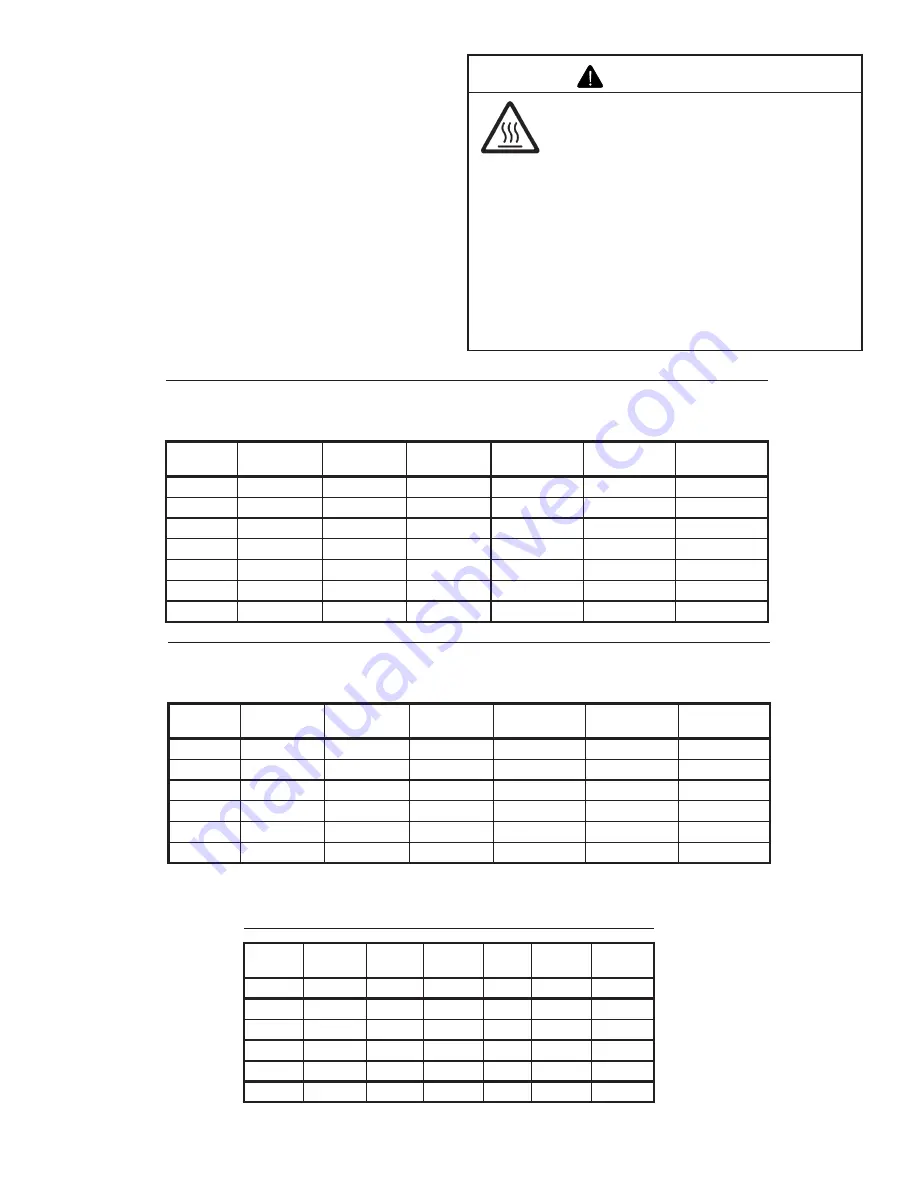

Asphyxiation Risk

This appliance produces carbon monoxide

(CO).

• The free opening areas (in square inches)

of the chimney damper as shown in the

following tables must be met.

• User must make sure damper is locked

open.

• The installer is responsible to ensure

proper ventilation of flue gases before

appliance is used.

Fire needs to draft properly for safe

operation.

WARNING

Table 1 for Factory Built Fireplaces

Free Opening Area (in square inches) of Chimney Damper for Venting combustion Products from Decorative

Appliances for Installation in Solid Fuel Burning Fireplaces.

Chimney Ht.

(Feet)*

18 in. Log Set

LP Gas

18 in. Log Set

Natural Gas

24 in. Log Set

LP Gas

24 in. Log Set

Natural Gas

30 in. Log Set

LP Gas

30 in. Log Set

Natural Gas

10

28.3

28.3

35.3

not approved

44.2

not approved

15

21.2

21.2

26.4

38.5

32.2

45.4

20

18.1

18.1

22.1

31.2

26.4

37.4

25

15.9

15.9

18.1

27.3

22.9

31.2

30

14.5

14.5

17.3

24.6

20.4

28.3

35

13.2

13.2

15.9

22.1

18.9

25.5

40

12.6

12.6

15.2

20.4

18.1

23.8

Table 2 for Masonry Built Fireplaces

Free Opening Area (in square inches) of Chimney Damper for Venting combustion Products from Decorative

Appliances for Installation in Solid Fuel Burning Fireplaces.

Chimney Ht.

(Feet)*

18 in. Log Set

LP Gas

18 in. Log Set

Natural Gas

24 in. Log Set

LP Gas

24 in. Log Set

Natural Gas

30 in. Log Set

LP Gas

30 in. Log Set

Natural Gas

6

41.7

41.7

49.2

64

56.6

71.4

8

38.7

38.7

45.5

59.7

52.4

66.9

10

35.2

35.2

41.7

54.3

48.2

60.2

15

32.0

32.0

37.7

48.8

43.2

54.1

20

28.8

28.8

34.3

44.4

39.8

49.1

30

26.5

26.5

31.2

40.3

35.9

44.5

* Height is measured from the hearth to the top of the chimney.

Minimum height is 6 ft.

G. Negative Pressure

Negative pressure results from the imbalance of air avail-

able for the fireplace to operate properly. Causes for this

imbalance include:

• Exhaust fans (kitchen, bath, etc.).

• Range hoods.

• Combustion air requirements for furnaces, water heaters

and other combustion appliances.

• Clothes dryers.

• Location of return-air vents to furnace or air

conditioning.

• Imbalances of the HVAC air handling system.

• Upper level air leaks: recessed lighting, attic hatch

opening, duct leaks.

Table 3 for Minimum Fireplace Dimensions

Burner

Style

Front

Opening

Depth

Height

Rear

Width

Natural

BTU

Propane

BTU

SBS18

27 In.

16 In.

18 In.

19 In.

44,000

40,000

SBS24

34 in.

20 in.

18 in.

22 in.

73,000

61,000

SBS30

40 in.

20 in.

18 in.

29 in.

80,000

70,000

SBSIII18

32 in.

23 in.

22 in.

21 in.

88,000

80,000

SBSIII24

34 in.

23 in.

22 in.

22 in.

88,000

80,000

SBSIII30

40 in.

23 in.

22 in.

29 in.

92,000

82,000