1 4

TROUBLESHOOTING

Note :

All troubleshooting

items are listed in order of

operation.

WARNING:

Only a qualified

service person should service and

repair heater.

CAUTION:

Never use a wire,

needle, or similar object to clean

ODS/pilot. This can damage

ODS/pilot unit.

OBSERVED PROBLEM

When ignitor button is pressed in,

there is no spark at ODS/pilot.

When ignitor button is pressed in,

there is a spark at ODS/pilot but

no ignition.

ODS/pilot lights but flame goes out

when control knob is released.

POSSIBLE CAUSE

1. Ignitor electrode is positioned

wrong.

2. Ignitor electrode is broken.

3. Ignitor electrode is not connected

to ignitor cable.

4. Ignitor cable is pinched or wet.

5. Broken ignitor cable.

6. Bad piezo ignitor.

1 . G a s s u p p l y i s t u r n e d o f f o r

equipment shutoff valve is closed.

2. Control knob not fully pressed in

while pressing ignitor button.

3. Air in gas lines when installed.

4. ODS/pilot is clogged.

5. Gas regulator setting is not correct.

6. Control knob not in PILOT position.

7. Depleted gas supply .

1. Control knob is not fully pressed

in.

2. Control knob is not pressed in

long enough.

3. Equipment shutoff valve is not

fully open.

4. Thermocouple connection is loose

at control valve.

5. Thermocouple damaged.

6. Control valve damaged.

REMEDY

1. Replace ignitor.

2. Replace ignitor.

3. Reconnect ignitor cable.

4. Free ignitor cable if pinched by

any metal or tubing. Keep

ignitor cable dry.

5. Replace ignitor cable.

6. Replace piezo ignitor.

1. Turn on gas supply of open

equipment shutoff valve.

2. Fully press in control knob

while pressing ignitor button.

3. Continue holding down control

knob. Repeat igniting operation

until air is removed.

4. Clean ODS/pilot (see Cleaning

and Maintenance, Page 13) or

replace ODS/pilot assembly

5. Replace gas regulator.

6. Turn control knob to pilot position.

7. Contact local propane/LP gas

campany.

1. Press in control knob fully.

2. After ODS/pilot lights, keep control

knob pressed in 30 seconds.

3. Fully open equipment shutoff valve

4. Hand tighten until snug, then

tighten 1/4 turn more.

5. Replace thermocouple.

6. Replace control valve.

Summary of Contents for HB06ML-1

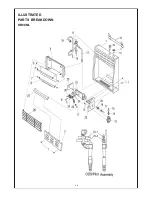

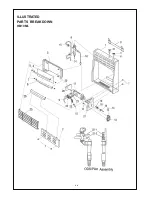

Page 18: ...1 8 ILLUSTRATED PARTS BREAKDOWN HB06ML ...

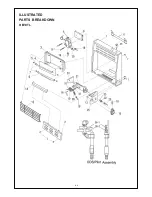

Page 20: ...2 0 ILLUSTRATED PARTS BREAKDOWN HB10ML ...

Page 22: ...2 2 ILLUSTRATED PARTS BREAKDOWN HB10TL ...

Page 24: ...2 4 ...