Hearthstone Quality Home Heating Products, Inc.

Bristol DX Model 8763

20

GAS CONNECTIONS

When threads are tightened, the valve must be held

at

the

designated

clamping

areas

(see

Figure 15).

DO NOT apply pressure to top casting or

plastic cover.

Connection Main Gas (Tubing connections)

1. Do NOT use pipe joint compound or

Teflon®/PTFE tape.

2. Slip nut and ferrule over

tubing.

3. Slide nut and ferrule into place, and insert

tubing into inlet/outlet connection until it

bottoms. Turn until finger-tight.

4. Use a wrench to tighten nut about 1 turn beyond

finger tight.

Connection Main Gas (Pipe Connections)

1. Do NOT use Teflon®/PTFE tape.

2. Pipe to be inserted into the valve must be the

proper thread length and to gauge. Thread

that IS cut too long can cause distortion or

malfunction if inserted too deeply.

3. Apply a moderate amount of approved

pipe\sealant to the pipe only, leaving the

two end threads bare.

3. Connect pipe to valve inlet and outlet.

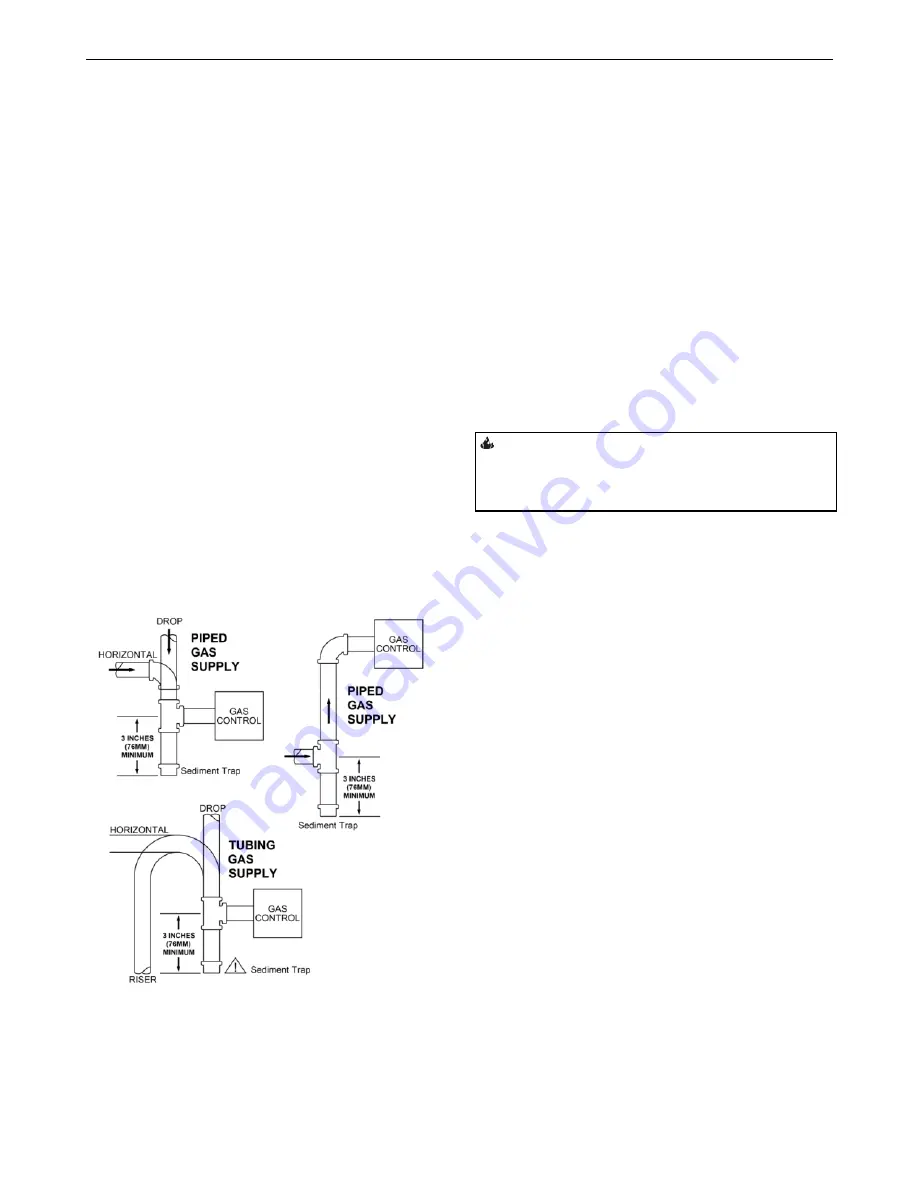

Figure 14

– Sample Gas Supply Sediment Traps

PERFORM INITIAL GAS LEAK TEST

1. Check carefully for gas leaks immediately after

the appliance has been installed and the gas

turned on.

Do this before attempting to operate

the appliance or other gas burning device.

1. Use an approved non-corrosive leak detection

fluid, or other approved leak detection method,

around the diaphragm flanges, pipe connections,

seal cap, and all other joints. Bubbles indicate a

leak.

2. If no leakage is detected, proceed with the

instructions listed on page 20 to light the main

burner and perform a secondary leak check of the

appliance gas supply system.

5. If a leak is detected, tighten pipe connections

(including adapters) according to "GAS

CONNECTIONS" (page 20).

WARNING

Absolutely no leakage should occur, otherwise

there is a danger of fire or explosion depending upon

conditions. Never use if leakage is detected.

Pre-Ignition Checks

WIRING CONNECTIONS

(See

Figure 13

, page 16)

• Assure all components are connected according to

the wiring diagram.

• When GV60 components are installed, make

sure they are not exposed to dirt, oil, grease or

other chemical agents.

• Do NOT permit foreign particles under plastic

cover.

Thermocouple Circuit

Total resistance of thermocouple circuit should be

minimized to ensure proper operation.

NOTICE: Keep connection of the Mertik Maxitrol

interrupter block interrupter block and thermocouple

clean and dry. Avoid severe

bending of the

thermocouple tubing during installation (min. 1"

radius:2.5 cm) as this may cause it to fail. If the Mertik

Maxitrol interrupter block must be removed for any

reason, following the steps below to re-install:

• Tighten interrupter block into valve1/4 turn

beyond finger tight (2...3 Nm).

• Slide cables into plastic insert.

•

Slide plastic insert with cables into the brass

interrupter block.