Hearthstone Quality Home Heating Products, Inc.

Bristol Model 8762

31

Odors and Impurities

A heater of this type may produce odors during

heater operation at any time due to impurities that

may exist in the immediate area around the unit.

Sources of impurities can be cleaning solvents, paint

solvents, cigarettes, candles, smoke, pet hair, dust,

adhesives, new carpet, and/or textiles. Such odors

will eventually dissipate. However, opening a

window or otherwise providing additional ventilation

to the area can alleviate the condition sooner. If any

odor persists, find and remove the cause, or contact

your dealer or an authorized service technician.

Initial Adjustments

Once the Bristol is set in place, connected and

assembled as described in the Clearances To

Combustibles,

Venting

Components

&

Configurations, Electrical Connections, and Gas

Supply and Connections sections of this manual, the

unit is ready to be lit and adjusted to its particular

installation. Hearthstone tests each unit prior to

shipment, so ignition should take place without

failure. However, a number of small adjustments

may be necessary to compensate for variations in

gas pressure, altitude, and other factors particular to

each installation.

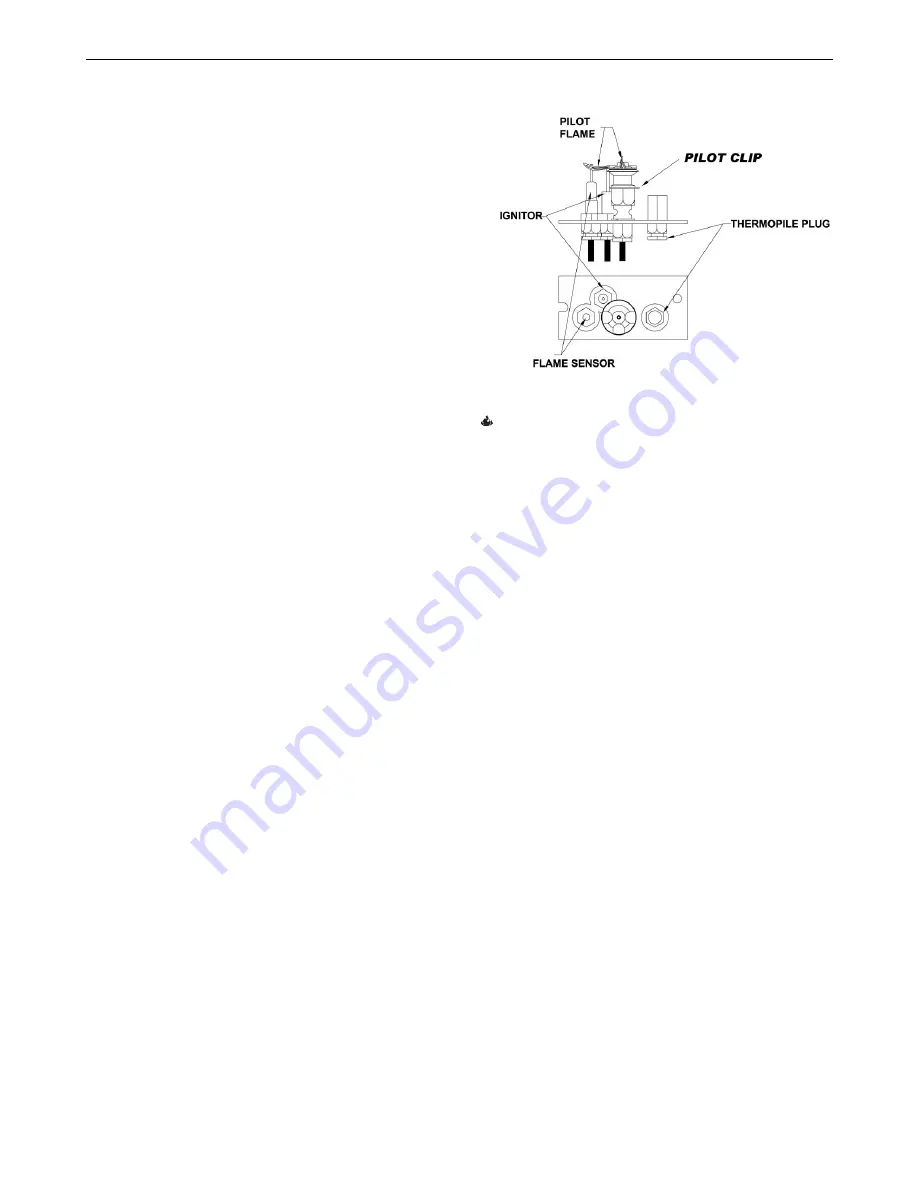

Pilot Adjustment

The pilot light is preset by the manufacturer and

should not need adjustment. The pilot light flame

should be large enough to engulf the sensor

(refer to

Figure 30)

and to reach the light off ports on the

burner but not so large as to create excessive noise

or consume excessive gas.

However, it can be

adjusted by means of the pilot light adjustment

screw located on the gas control valve. Controlling

the Bristol may become erratic, nonexistent, or the

unit may go out, if the pilot flame is too small or

misdirected away from the flame sensor.

Figure 28 - Pilot Flame Pattern

WARNING: THE CONTROL HAS AN INTERLOCK

DEVICE. IF THE STOVE HAS BEEN LIT, IT WILL

NOT RELIGHT AGAIN IMMEDIATELY. AFTER

SHUTTING OFF ALL GAS FLOW, THE PILOT

BURNER CANNOT BE RELIT UNTIL THE FLAME

SENSOR

HAS

COOLED,

ALLOWING

THE

ELECTROMAGNET TO BE RELEASED

(APPROX.

60 SEC.)

.

Air Shutters

The air shutters are used to regulate the air-to-gas

combustion mixture of each burner, which in turn

influences the size and color of the flames. The air

shutters are factory positioned in the general

location needed for testing the unit with natural gas

(NG) and minimum venting. However, if the unit is

not burning as well as it should in your installation,

then the air shutters may need adjusting.

To determine if an air shutter needs adjustment, it is

necessary to view the flame pattern with the burner

output set at its highest setting. Allow the unit to

operate for at least 10 minutes to allow the entire

unit to reach temperature, and for the flame pattern

to stabilize. Generally, the more air (open shutter) in

the mixture, the bluer the flame. Less air (closed

shutter) results in a more yellow flame, but too little

air will result in incomplete combustion, low

efficiency and a dirty burn. There are two simple

guidelines to aid in determining the correct flame

pattern:

1. If the flame just above the surface of the

burner or at the base of the logs is

completely blue, the air shutter may be open

too far;

2. If the flame is dirty, sooty, or licks the top of

the firebox, the air shutter may be closed too

far.