HearthStone Quality Home Heating Products, Inc.

Modena Model #8140

12

V

ENTING

C

OMPONENTS

&

C

ONFIGURATION

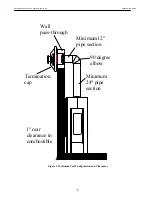

Do not vent the Modena jointly with any other solid fuel or

gas appliance. Vent the Modena directly to the outside of

the building using a proper termination as listed in this

manual. The only types of venting pipe approved for use

with your Modena Direct-Vent stove is Simpson Dura-

Vent’s GS, AmeriVent Direct, Selkirk Direct Temp™ and

Secure Vent Direct-Vent Pipe. The venting configuration

diagram is shown in

Figure 7

. After determining the proper

venting configuration for your stove, select the vent system

that will accommodate your installation.

Caution: Ensure there is no wiring or plumbing in

the chosen location.

Caution: Do not recess venting terminations into a

wall or siding.

Note:

If further direction is needed for installation, please

refer to the venting instructions, which are provided with

the venting components.

Acceptable Direct-Vent Termination Cap

Locations

The vent/air intake termination clearances above the high

side of an angled roof are as follows:

Roof Pitch

Feet

Meters

Flat to 6/12

1

0.3

7/12 to 9/12

2

0.6

10/12 to 12/12

4

1.2

13/12 to 16/12

6

1.8

17/12 to 21/12

8

2.4

Listed are Simpson Dura-Vent, AmeriVent Direct, Selkirk

Direct Temp™

and Secure Vent components acceptable for

installation, along with the minimum venting kit available.

The venting system must be comprised of the appropriate

venting components as specified.

A

PPROVED

V

ENTING

S

YSTEM

C

OMPONENTS

(The following are components that are available, BUT

NOT necessary for all installations)

90

0

Elbow

Vertical Vent Cap

45

0

Elbow

36” Snorkel

6" Straight

9" Straight

(Simpson only

)

Vinyl Siding Standoff 4” x

6 5/8"

12" Straight

Round Ceiling Support

24" Straight

Thimble Covers

36" Straight

Wall thimble

48" Straight

11"-14 5/8" Adjustable Pipe

Horizontal Vent Cap

C

HIMNEY

L

INER

S

YSTEM

Direct-Vent Chimney Liner Termination Kit

Chimney Liner Flex

Co-Linear Flex Connector

Co-Axial to Co-Linear Appliance Connect (

Masonry

approved, not to exceed 16’ measured from the stove

top

)

M

INIMUM

V

ENT

K

IT

Vent connector (Provided with unit)

24” Straight

90 degree elbow

12” Straight

Wall Thimble Cover

Wall Thimble

Horizontal Vent Cap

Dry fit your venting and take a measurement. Pipe

dimensions will vary by manufacturer and supplier.

I

NSTALLATION

I

NSTRUCTIONS FOR THE

S

TANDARD

H

ORIZONTAL

T

ERMINATION

M

INIMUM

V

ENTING

K

IT

1.

Install the 24” straight section on top of the vent

connector.

2.

Place the 90 degree elbow on the 24” section. Facing

the direction expected to penetrate the wall.

3.

Attach the 12” straight section to the 90 degree elbow.

Move the stove and pipe assembly backwards until the

12” straight is flush against the wall. Pull up on the

pipe to ensure that there is a ¼” per foot rise coming

out of the stove to the wall.

4.

Draw a circle around the pipe. Use the center of this

circle as the center point of the 10” x 10” square wall

pass through. Cut and frame the wall pass through

opening.

5.

Place the interior wall thimble into the 10” x 10” wall

pass through. Secure it with 4 screws (not provided).

Install the exterior portion of the thimble in similar

fashion, overlapping the 2 sections.

Caution:

For buildings with vinyl siding, install

a vinyl siding standoff between the vent cap and

the exterior wall.

6.

Install the horizontal vent termination on the outside of

the wall. Ensure both of the retaining straps extend

through interior wall thimble. Before attaching the vent

termination to the outside of the house, run a bead of

non-hardening mastic around its’ outside edges to

ensure a good seal between it and the wall.

Ensure the

arrow on the end cap points up

. Secure the cap to the

wall with appropriate screws.

7.

Move the stove and vent pipe into position. Make sure

the 12” vent pipe extends into the horizontal vent cap a

minimum of 1-1/4”. Secure the vent using the straps

from the horizontal vent termination to the interior 6”

pipe with 2 sheet metal screws, keeping the screws as

close to the wall thimble as possible. Bend or cut any

excess strapping, so that it is not visible after the

installation is complete.