Hearthstone

Quality

Home

Heating

Products ,

Inc.

ODEL

8521

Sterling

“G”

B-Vent

8

V

ENTING

/C

HIMNEY

R

EQUIREMENTS

Normally Aspirated Chimneys

The Sterling is a high efficiency gas heater. With

operating efficiencies as high as 80%, most heat

output is retained within the living space, with

minimal heat leaving the room via the chimney.

However, some heat is required in all chimneys in

order to establish and maintain a draft. Since most

of the heat is retained in the living space with

minimal heat entering the chimney, it is imperative

that the chimney/venting system be properly sized

and installed in order to establish and maintain the

draft required for the unit to function.

The Sterling must be properly connected to a 4"

(102-mm) diameter type B-1 vent which is

constructed and installed in accordance with

NFPA54 and NFPA211. Single wall vent pipe may

be used within the same room as the Sterling so

long as adequate (6" or 152 mm) clearance is

maintained from the single wall pipe to combustible

surfaces. The single wall vent pipe must connect to

double-wall type B-1 vent at the first wall or ceiling

penetration, and continue with type B-1 vent from

thereon. The minimum clearance from type B-1 vent

to combustibles is 1" (25-mm).

Connect the single wall vent pipe or the B-1 vent

to the flue collar located on the rear surface of the

unit using 3 sheet metal screws. For wall, roof or

partition penetration, refer to the current edition of

ANSI Z223.1 or CAN1-B149 for instructions and

clearances to combustibles. The Sterling can be

connected to an existing, properly constructed

masonry or prefabricated chimney so long as the

type B-1 vent is extended through the entire length

of the chimney. An annual inspection is required to

confirm that the vent is unobstructed. The venting

can not be connected to a flue serving a solid fuel

appliance. It can however, be connected to a flue

serving another gas or oil appliance, so long that it is

in compliance with the National Fuel Gas Code.

Type B-1 vent pipe is intended primarily for

installation inside buildings to provide an essentially

vertical passageway for flue gases from the vented

gas appliance to the outside air. When it is

impractical to install B-1 vent pipe inside a building,

it may be installed outdoors provided that it is: 1)

certified for outside installation, 2) installed in

accordance with the manufacturer's installation

instructions and 3) adequately chased (enclosed)

and insulated (per Venting Tables, Category I -

Central Furnaces, AGA and GAMA. July 1991;

Standards for Gas Vents, National Standards of

Canada; and CAN/CGA-B149.1-M91). Exterior B-1

venting not chased and insulated below the roof line

may experience continuous condensation depending

on the locality. B-1 vent pipe passing through an

unused masonry chimney flue is not considered to

be exposed to the outdoors.

Four inch flexible pipe can be used in place of

Type B-1 vent pipe wherever it is impractical or

impossible to install rigid Type B-1 vent pipe.

However, flexible pipe is less desirable than B-1

vent pipe, because there is a greater heat loss along

the length of flex pipe which may result in a reduced

or unacceptable draft.

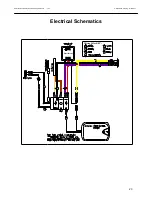

Draft Hood/Down Draft Sensor/Spill

Switch

The Sterling has a draft hood as part of its rear

assembly. The draft hood must not be altered or

obstructed. The Sterling must be installed so that

the draft hood is in the same atmospheric pressure

zone as the combustible air inlet for the unit. The

Sterling cannot and must not be connected to an

outside air source; the unit must take its combustion

air from the living space in which it is installed.

The draft hood is equipped with a safety shutoff

down draft sensor switch (spill switch) which is

located in the draft hood just beneath the flue collar

on the rear of the unit. This switch is designed to

sense a loss of draft within the chimney. The down

draft sensor switch is wired in series with the pilot

thermocouple and is typically in the closed position.

Should the Sterling fail to establish or lose its

draft while in operation, hot exhaust gasses will spill

into the room through the bottom of the draft hood

instead of exiting the draft hood via the flue collar

and venting to the outdoors. When this undesirable

down draft condition occurs the hot gasses spilling

out of the draft hood will heat the spill switch causing

it to open which turns the unit off.

Do not modify, disconnect or otherwise defeat the

purpose of the down draft sensor switch. If your

stove shuts off during normal operation, it is

indicative of an unsafe venting condition which must

be corrected. Operation of this unit when not

properly connected to a properly installed and

maintained venting system or tampering with the

vent safety shutoff system can result in carbon

monoxide (CO) poisoning and possible death.

Power Venting

For applications where it is impractical or

impossible to extend B-1 vent pipe to above the

existing roof line, the Sterling can be vented using a

power vent. A power vent is essentially a

specialized electric fan mounted on the outer wall of

the building which is connected to the heater via flue

pipe. When the thermostat calls for heat, the power

vent turns on and creates a draft in the flue pipe

similar to the draft created by a properly functioning

conventional chimney. The Sterling then operates in

a normal fashion, satisfied by the simulated draft. A

series of interlocking safety devices prevents

operation of the heater unless the power vent is

operating properly. Both the Sterling and the power

vent are controlled by the wall thermostat and

neither will operate if there is a power failure. For

installations requiring power venting,

use only an

AGA (U.S.) or CGA (Canada) listed unit.

The power

vent supplier will in turn supply the power vent

installation instructions.