Hearthstone

Quality

Home

Heating

Products ,

Inc.

ODEL

8521

Sterling

“G”

B-Vent

9

Gas Supply

F

ACTORY

-R

EADY FOR

G

AS

O

PERATION

All Sterlings are shipped from the manufacturer

fully assembled and ready for natural gas or LP

(liquid propane) gas operation with minor

adjustment. However, if the Sterling needs to be

converted from natural gas to LP or from LP to

natural gas, conversion of the unit must be

performed by qualified service personnel using the

manufacturer-supplied optional conversion kit.

Follow the conversion instructions supplied with the

conversion kit.

"For installations from 2,000-4,500 ft. (610-

1370m), the orifice sizes (DMS) for natural and

propane gas are 45 and 56 respectively. See data

plate for additional information. For high altitude

installations, consult the local gas distributor or the

authority having jurisdiction for proper rating

methods. If the installer must convert the unit to

adjust for varying altitudes, the information sticker

must be filled out by the installer and adhered to the

appliance at the time of conversion.

The conversion shall be carried out by a

manufacturer’s authorized representative in

accordance with the requirements of the

manufacturer, provincial or territorial

authorities having jurisdiction and in

accordance with the requirement of the

CAN/CGA 2.17 Installation Codes.

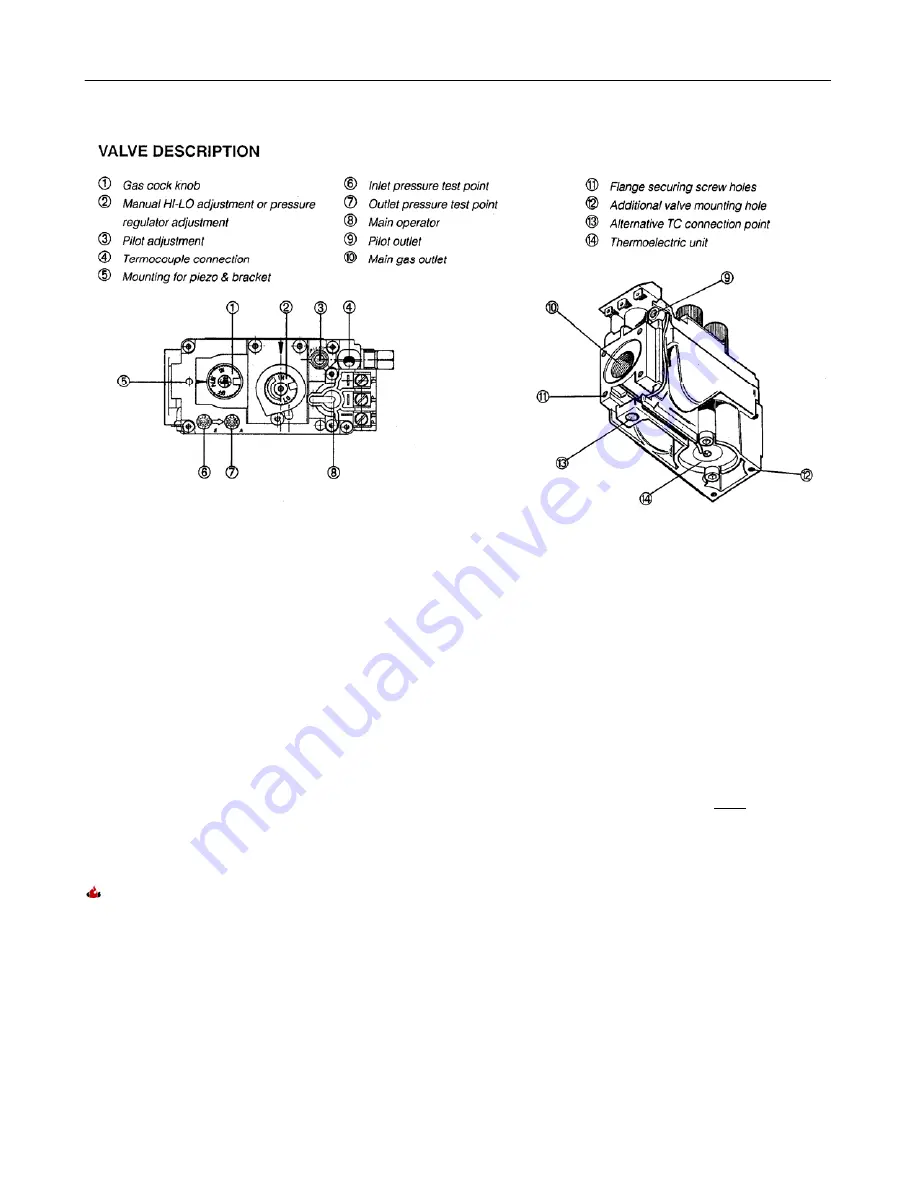

Gas Connection

The gas supply line connection is made to the

Sterling's gas control valve just inside the right rear

leg of the unit using a d" male NPT fitting . The

supply line should be ½" diameter or appropriately

sized to provide a sufficient gas supply to meet the

maximum demand of the unit without undue loss of

pressure. We recommend a flexible line to avoid

undue mechanical load on the valve and to ease

thread alignment.

The unit must be installed and connected in

accordance with local codes, or in absence of local

codes, with the most current edition of the

National

Fuel Gas Code ANSI Z223.1 CAN/CGA B149.

The supply line must include a manual shut-off valve

and union so that the unit can be disconnected for

servicing. Also, a sediment trap must be installed

upstream of the heater. The sediment trap is

installed to prevent moisture and contaminants from

passing through the pipe to the heater controls. A

1/8" N.P.T. plugged tapping is recommended for

ease of pressure and gauge connection tests.

Gas Pressure Adjustment

Once connected to the gas supply, the supply

line and manifold gas pressures must be tested.

The supply line pressure is tested, to ensure it

meets the minimum gas supply pressure as listed in

the Specifications for the type of fuel in use

(natural

gas or LP)

, by connecting a manometer to the

supply line and adjusting the incoming pressure if

necessary to meet the required supply line pressure