HearthStone Quality Home Heating Products Inc

STERLING Ht Gas-Fired Direct Vent heater

to loosen the bolt. Sliding the control levers forward

or backward will open and close the shutters. This

nut is hot and should not be touched. Use only metal

tools for this adjustment. Sliding forw ard opens the

air shutter, and sliding ba ckward closes it. Tighten

the nut after making adjust ment. The air shutter is

factory set and only a qualified gas technician should

make adjustments.

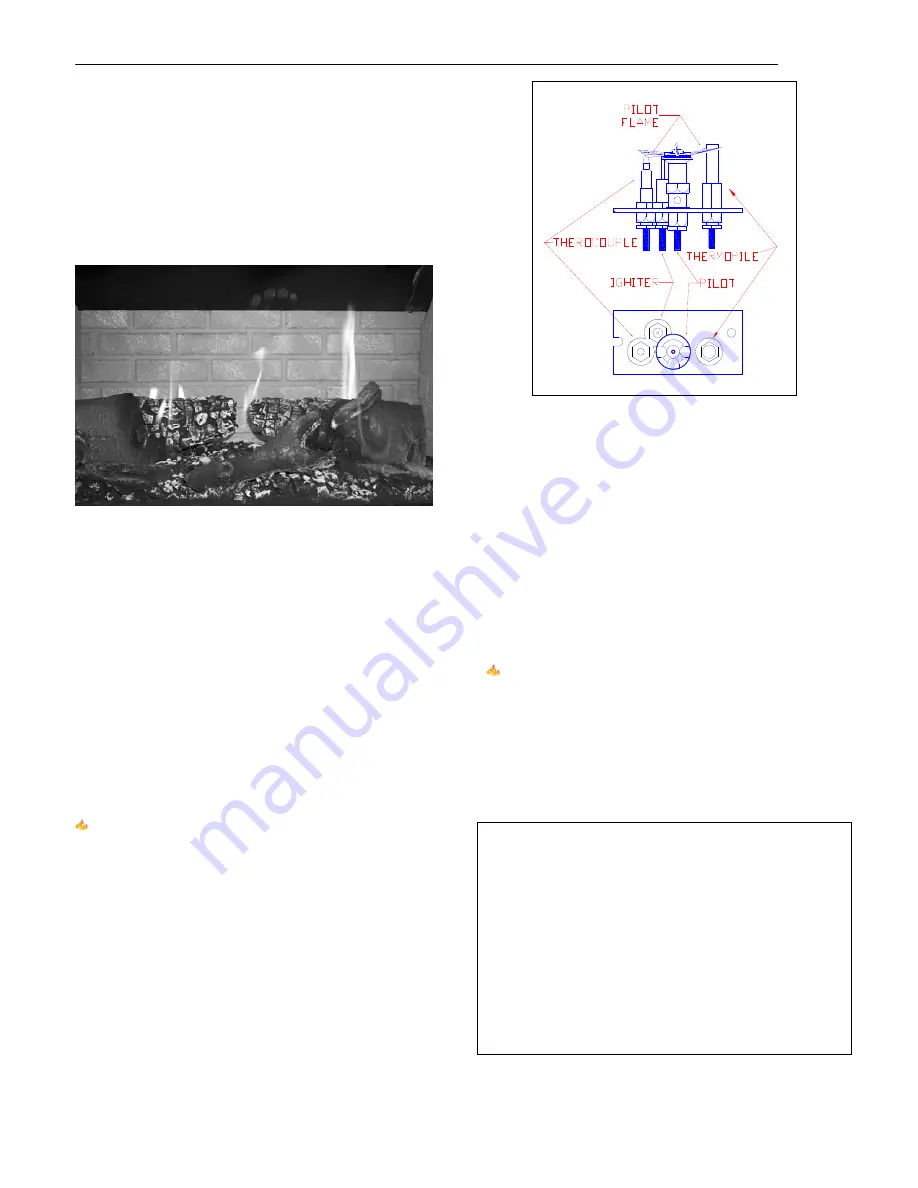

(refer to the image below to see a

typical flame pattern)

P

ILOT

A

DJUSTMENT

The pilot light is preset by the manufacturer and

should not need adjustment. The pilo t light flame

must be large enough t o engulf the th ermopile and

thermocouple located next to the pil ot, but not so

large as to create excessive noise or consume

excessive gas.

(refer to the image below)

However, it

can be adjusted by means of the pilot light adjustment

screw located on the gas control valve. Access the

gas control valve as described in the Gas Connections

section, on page 16. Note that the pilot flam e must

engulf the t hermopile so that the th ermopile can

generate sufficient m illi-voltage (325 t o 500-mv) to

power the millivolt gas control valve.

W

ARNING

!

The control has an interl ock device. If

the stove has been lit, it will no

t relight

immediately. After shutting off all gas flow, the

pilot burner cannot be relit until the thermocouple

has cooled, allowing th e electromagnet to be

released

(Approx. 60 sec.)

. The gas control knob is

designed to operate by hand. Do not use any tools

during this operation.

G

AS

C

ONVERSIONS

All Sterling stoves are set up for use with Natural

Gas when built. However, these uni ts are easily

converted for use with LP, and visa versa. Th e

instructions provided wit h the included conversion

kit must be followed.

Only a Qualified Gas

Technician should do the conversion.

For checking, and pr operly adjusting, the manifold

pressure, refer to the

Gas Connection section on page

16

of this manual.

Leak test before, and after, lighting the stove

.

Fill out the label provided on back of the stove. The

input rate of the heater is verified by checking the

manifold pressure. If the manifold pressure is

correct, then the input rate is also correct. Be sure to

check the ma nifold pressure and properly adjust the

pilot and main burner flames.

HIGH ALTITUDE CONVERSIONS

For high altitude installations, (610-1370 meters,

2000-4500 feet) the orifice sizes (DMS) for NG gas

is 52 & 39 for 4”x6” pipe and 44 & 53 for 5”x8”

pipe. For LP gas, the orifice sizes are 54 & 64 for

4”x6” pipe and 56 & 64 for 5”x8” pipe. See data

plate for additional information. For high altitudes

consult the local gas distributor, or the authority

having jurisdiction for proper rating methods. If a

conversion is necessary, the installer must fill out the

conversion label provided with the kit and place it on

the unit.

21