Hearthstone Quality Home Heating Products, Inc

STOWE Model 8324

13

M

INIMUM

V

ENTING

I

NSTALLATION

I

NSTRUCTIONS

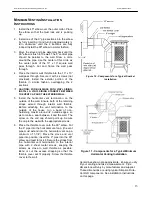

1. Install the 45º elbow over the outer collar. Place

the elbow so that the twist lock end is pointing

up.

2.

Install one of the 9” pipe sections into the elbow

by fully inserting it and turning approximately ¼

turn clockwise, until the 2 sections are fully

locked. Install the 90º elbow in similar fashion.

3. Move the stove and pipe assembly back until the

90º elbow is flush to the wall. The 9” vertical pipe

should be parallel to the wall. Draw a circle

around the pipe. Use the center of this circle as

the center point of the 10” x 10” square wall

pass through. Cut and frame the wall pass

through.

4. Place th

e interior wall thimble into the 10” x 10”

wall pass through. Secure it with 4 screws (not

provided). Install the exterior portion of the

thimble in similar fashion, overlapping the 2

sections.

CAUTION: FOR BUILDINGS WITH VINYL SIDING,

INSTALL A VINYL SIDING STANDOFF BETWEEN

THE VENT CAP AND THE EXTERIOR WALL.

5. Install the horizontal vent termination on the

outside of the wall. Ensure both of the retaining

straps extend through interior wall thimble.

Before attaching the vent termination to the

outside of the house, run a bead of non-

hardening mastic around its’ outside edges, so

as to make a seal between it and the wall. The

arrow on the end cap should point up. Secure

the cap to the wall with the appropriate screws.

6. Place the thimble cover onto the 90º elbow. Put

the 9” pipe into the horizontal vent cap, (the vent

pipe must extend into the horizontal vent cap a

minimum of 1-

1/4”). Move the stove and vent

pipe into position, insert the 9” pipe into the 90º

elbow and twist to lock it. Secure the straps from

the horizontal vent termination to the interior

pipe with 2 sheet metal screws, keeping the

screws as close to wall thimble as possible.

Bend or cut the excess strapping so that the

thimble cover will fit properly. Screw the thimble

cover to the wall.

Figure 11 - Components for a Typical Minimum

Horizontal Venting Installation

Centerlines shown are approximate. Ensure you dry

fit your venting and take a measurement. Pipe

dimensions will vary by manufacturer and supplier.

These dimensions are using typical Simpson Dura-

Vent GS components. See installation instructions

on this page.

Figure 10 - Components for a Typical Snorkel

Installation