Hearthstone Quality Home Heating Products, Inc.

STOWE Model 8324

18

WARNINGS

Fire or Explosion Hazard. Can cause property

damage, severe injury,

or

death. Do NOT bend

tubing at gas valve connection point after

compression fitting has been tightened. This

can result in gas leakage at the connection.

Use new properly prepared pipe free from metal

or material chips. When tubing is used, assure

that ends are square, de-burred and clean. All

tubing bends must be smooth and free of

distortion.

Do NOT over tighten connections.

Over tightening can damage the control body

resulting in leakage or control malfunction.

Do NOT remove screws from the gas valve

.

Do

NOT adjust and/or alter any components

marked with tamper indicating paint. Motor

knob is not to be removed.

Turn off gas supply at the appliance service

valve before starting installation, and perform a

Gas Leak Test after the installation is complete.

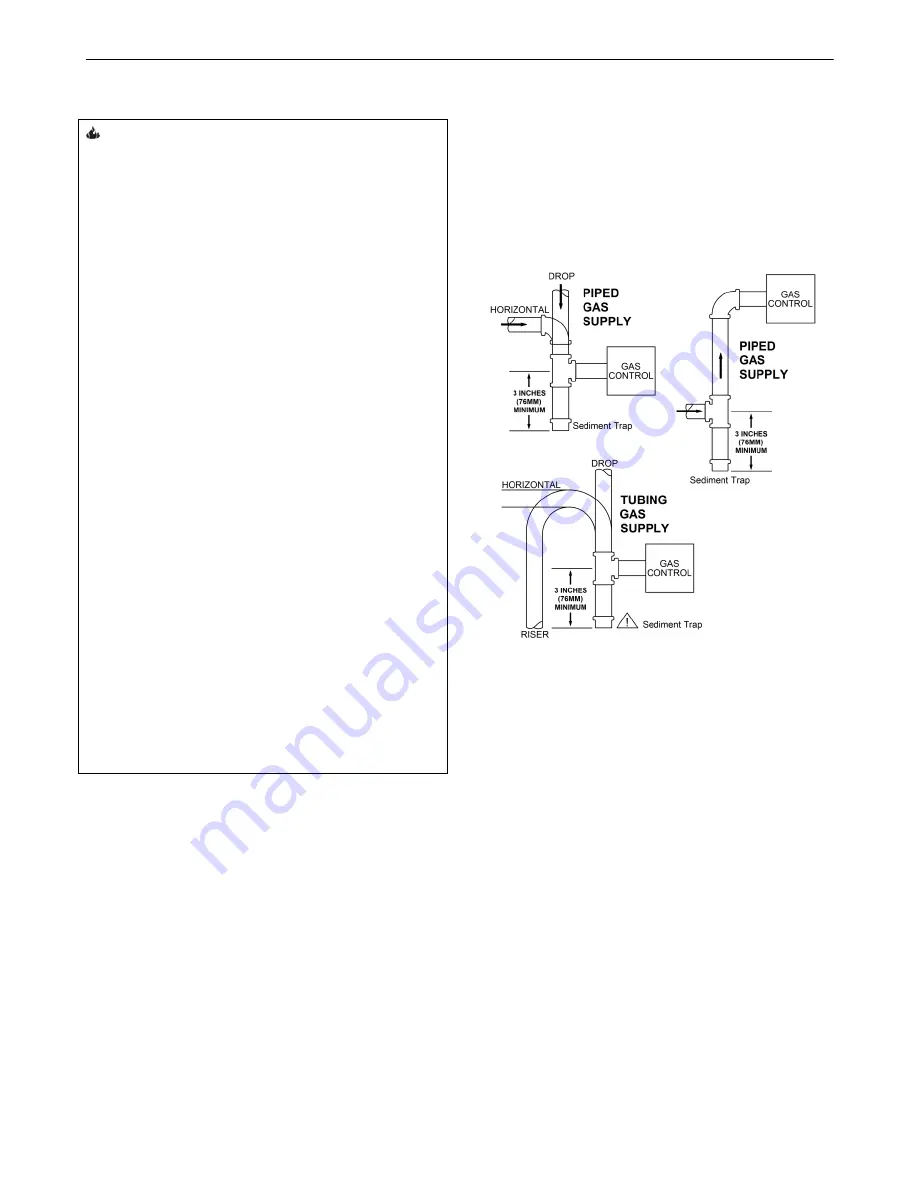

Install the sediment trap (where required) in the

gas supply line to prevent contamination of the

gas valve (

see figure 16

).

Use only your hand to push in or turn, the

gas Control knobs. Never use tools. If a

knob will not push in or turn by hand, do

NOT try to repair it. Call a qualified service

technician. Force or attempted repair will

void warranty and can result in a fire or

explosion.

GAS CONNECTIONS

Connection Main Gas (Tubing connections)

1. Do NOT use pipe joint compound or

Teflon®/PTFE tape.

2. Slip nut and ferrule over

tubing.

3. Slide nut and ferrule into place, and insert

tubing into inlet/outlet connection until it

bottoms. Turn until finger-tight.

4. Use a wrench to tighten nut about 1 turn beyond

finger tight.

Connection Main Gas (Pipe Connections)

1. Do NOT use Teflon®/PTFE tape.

2. Pipe to be inserted into the valve must be the

proper thread length and to gauge. Thread

that IS cut too long can cause distortion or

malfunction if inserted too deeply.

3. Apply a moderate amount of approved

pipe\sealant to the pipe only, leaving the

two end threads bare.

1. Connect pipe to valve inlet and outlet.

Figure 16

– Sample Gas Supply Sediment Traps

PERFORM INITIAL GAS LEAK TEST

1. Check carefully for gas leaks immediately after

the appliance has been installed and the gas

turned on.

Do this before attempting to operate

the appliance or other gas burning device.

1. Use an approved non-corrosive leak detection

fluid, or other approved leak detection method,

around the diaphragm flanges, pipe connections,

seal cap, and all other joints. Bubbles indicate a

leak.

2. If no leakage is detected, proceed with the

instructions listed on page 21 to light the main

burner and perform a secondary leak check of

the appliance gas supply system.

5. If a leak is detected, tighten pipe connections

(including adapters) according to "GAS

CONNECTIONS" (page 17).