Hearthstone Quality Home Heating Products, Inc.

Tudor Model #8120

G

AS

S

UPPLY

&

C

ONNECTIONS

WARNING: THE UNIT MUST BE INSTALLED AND

CONNECTED IN ACCORDANCE WITH LOCAL

CODES, OR IN THE ABSENCE OF LOCAL CODES,

WITH THE MOST CURRENT EDITION OF THE

NATIONAL FUEL GAS CODE ANSI Z223.1 (NFPA

54) OR CAN/CGA B149 INSTALLATION CODE.

NOTICE: A qualified technician must connect

the heater to the gas supply and leak test the

unit before it is approved for use. Consult all

codes.

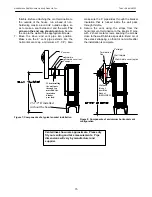

NFPA Code, and Hearthstone require the use of

a dedicated sediment trap just upstream of the

unit. Damage to the valve, or other components

due to the lack of a sediment trap are not

covered by warranty.

3" MIN.

Cap

Nipple

To Equipment

Inlet

Tee Fitting

Gas Supply

Inlet

Figure 11: Typical Sediment Trap (Required in all

installations)

G

AS

C

ONNECTIONS

The gas supply connection is made to the Tudor’s

gas control valve in the middle of the lower rear of

the stove, using a 3/8” male NPT fitting. The supply

line should be ½” diameter, or appropriately sized to

provide a sufficient gas supply to meet the maximum

demand of the unit without undue loss of pressure.

We recommend a flexible line to avoid undue

mechanical load on the valve and to ease thread

alignment, but refer to local codes.

CAUTION: CHECK GAS TYPE!

G

AS

S

UPPLY

This appliance and its individual shutoff valve must

be disconnected from the gas supply piping system

during any pressure testing of that system at test

pressures in excess of ½ psig. The Tudor must be

isolated from the gas supply piping system by

closing its individual manual shutoff valve during any

pressure testing of the gas supply piping system at

test pressures equal to or greater than ½ psig.

G

AS

P

RESSURE

A

DJUSTMENT

NOTE: A QUALIFIED TECHNICIAN MUST

PERFORM THIS PROCEDURE!

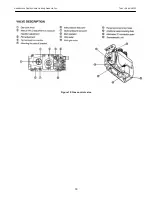

Once connected to the gas supply, the supply line

and manifold gas pressures must be tested. The

supply line pressure is tested, to insure it meets the

minimum gas supply pressure as listed in the

Specifications for the type of fuel in use (natural gas

or LP), by connecting a manometer to the supply

line and adjusting the incoming pressure if

necessary to meet the required supply line pressure

as listed in specifications. The manifold pressure tap

on the gas control valve, refer to

Figure 10

for

location.

19