Hearthstone Quality Home Heating Products, Inc.

TUDOR 8120 Gas-Fired Direct-Vent

cycling of the main burner, but the pilot remains lit

regardless of the thermostat setting. The only way to

turn the pilot off is to turn the gas control knob fully

clockwise to the “OFF” position.

T

O

T

URN

O

FF

G

AS

T

O

A

PPLIANCE

1. Set the thermostat to the “OFF” position or turn

the ON/OFF/T-STAT switch to the “OFF”

position.

2. If shutting the unit off for the non-heating

season, turn the gas control knob fully clockwise

to the “OFF” position. Do not force the knob to

turn.

A

IR

S

HUTTER

The air shutter is used to regulate the air-to-gas

combustion mixture, which in turn influences the size

and color of the flames. The air shutter is positioned

in the general location needed for the type of gas

being used, however, if the unit is not burning as

well as it should, then the air shutter may need

adjusting. The air shutter may need adjustment once

the unit has been installed to compensate for

variations in supply line pressure, restriction plate

position, altitude, gas type conversions, and other

variables.

To determine if the air shutter needs adjustment, it is

necessary to view the flame pattern with the variable

output control knob at its highest setting. Allow the

unit to operate for at least 10 minutes to allow the

entire unit to reach temperature, and for the flame

pattern to stabilize. Generally, the more air (open

shutter) in the mixture, the bluer the flame. Less air

(closed shutter) results in a more yellow flame, but

too little air will result in incomplete combustion, low

efficiency and a dirty burn. There are two simple

guidelines to aid in determining the correct flame

pattern:

1. If the flame at the base of the logs is

completely blue, the air shutter may be open

too far;

2. If the flame is dirty or licks the top of the

stove, the air shutter may be closed too far.

Some conditions cannot be corrected through air

shutter adjustment; an adjustment must be made to

the gas supply pressure or by changing the

restriction plate location. Qualified service personnel

must perform supply line/manifold gas line pressure

adjustments and restrictor plate adjustments. Do not

attempt to complete any part of the installation or

adjustment of this unit unless technically qualified to

do so.

A

IR

S

HUTTER

A

DJUSTMENTS

The air shutter adjuster, located under the valve

access door, in the lower front of the unit, is

adjustable while the stove is burning.

Use a 5/16” wrench to

l

oosen the air shutter

locking nut while holding the screw prior to

lighting the unit.

This nut will get very hot during

operation and will be difficult to loosen.

1. Turn the screw in to close the shutter or out

to open it. Use only metal tools for this

adjustment.

2. When the burner starts to rise while turning

the screw in, the shutter is fully closed. Stop

turning the screw in.

3. When the flame pattern is correct, tighten

the locking nut without turning the screw.

The air shutter is factory set, and only a qualified

gas technician should make adjustments.

Note:

Very little movement is needed to substantially

change the burn and flame patterns. Some

conditions cannot be corrected through air shutter

adjustment; an adjustment must be made to the gas

supply pressure. Supply line/manifold gas line

pressure adjustments must be performed by

qualified service personnel. Do not attempt to

complete any part of the installation or adjustment of

this unit unless technically qualified to do so.

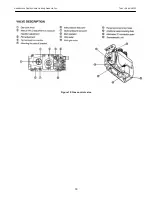

P

ILOT

A

DJUSTMENT

The pilot light is preset by the manufacturer and

should not need adjustment. The pilot light flame

should be large enough to engulf the thermopile and

thermocouple located next to the pilot, but not so

large as to create excessive noise or consume

excessive gas

.

However, it can be adjusted by

means of the pilot light adjustment screw located on

the gas control valve

(Refer to figure 10)

. Open the

valve door to access the pilot adjustment screw.

Note that the pilot flame must engulf the thermopile

so that the thermopile can generate sufficient milli-

voltage (325 to 500-mv) to power the gas control

valve. The flame on the pilot should look like

Figure

12

. Controlling the Tudor by the wall-mounted

thermostat may become erratic, nonexistent, or the

unit may go out, if the pilot flame is too small or

misdirected away from the thermopile.

25