Break-In Fire

SMOKE/SMELL EMITTED DURING INITIAL USAGE.

Some parts of the stove have been coated with a light

covering of protective oil. During initial operation of the

stove, this may cause smoke/smell to be emitted and is

normal and not a fault with the appliance, it is therefore

advisable to open doors and or windows to allow for

ventilation.

Lift the insulating lids to prevent staining the linings.

The firebox of your stove is made of superior materials -

cast iron and firebrick lining. Both materials can be broken

by a sharp blow or thermal shock. A little extra care should

be taken during the first six break-in fires. During this

period, it is important to let the cast iron and firebrick

slowly dry out and avoid thermal shock caused by strong,

hot fires.

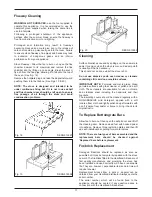

Directions of Flueway in Stove

Flue Chamber Damper

The adjustable flue chamber damper is for chimney draft.

The more it is closed, the easier it is to control the heat.

The line markings on the flue chamber enable you to

repeat the best settings to suit your chimney, from No. 1 in

a closed position to No. 6 fully open.

Open the damper fully before re-fuelling. Re-set the

damper to the position that has been found by experience

to give the best results with your chimney.

Do not try to obtain a fast increase in temperature by

opening the flue chamber damper to its fullest extent.

This results in most of the heat being wasted up the

chimney.

The flue chamber box has a removable door on the front

for cleaning access to the flueway. The stove is not to be

operated with this door removed. This could result in a

dangerous backdraft condition.

Chimney Sweeping

Sweep annually and inspect soot box at 3 monthly

intervals and remove any deposits. Stove must not be in

use and not had a fire for at least 16 hours.

NOTE: Sweep brushes must be of the type with wire

centres and guide wheels.

16

Fig. 16

DESN 515010

Fig. 17

DESN 515131