13

Heat & Glo • TIARA II-B • 7011-148 Rev. G • 10/12

NOTE:

(1) Installation requires a minimum of 6 in. (152mm)

horizontal run of vent with a 1/4 in. (6mm) rise run towards

the termination. Each 1 ft. (305mm) of horizontal venting

must include a 1/4 in. (6mm) rise. Never allow the vent

to run downward. This could cause high temperatures

and may present the possibility of a fire.

(2) The location of the horizontal vent termination on an

exterior wall must meet all local and national building

codes, and must not be easily blocked or obstructed,

see

Figure 4.4

on page 10.

(3) For installations requiring a vertical rise on the exterior

of the building, a snorkel kit is available with a 14 in.

(356mm) and a 36 in. (914mm) tall snorkel termination

cap. Follow the same installation procedures as used

for standard horizontal terminations. If the snorkel

termination must be installed below grade (i.e. basement

application), proper drainage must be provided to

prevent water from entering the snorkel termination. Do

not backfill around snorkel termination.

(4) Vertical clearances through a wall require 2 in. (51mm)

off the top of the venting pipe and 1 in. (25mm) off the

sides and bottom.

HOT

HOT

WOOD

SCREW

WALL THIMBLE

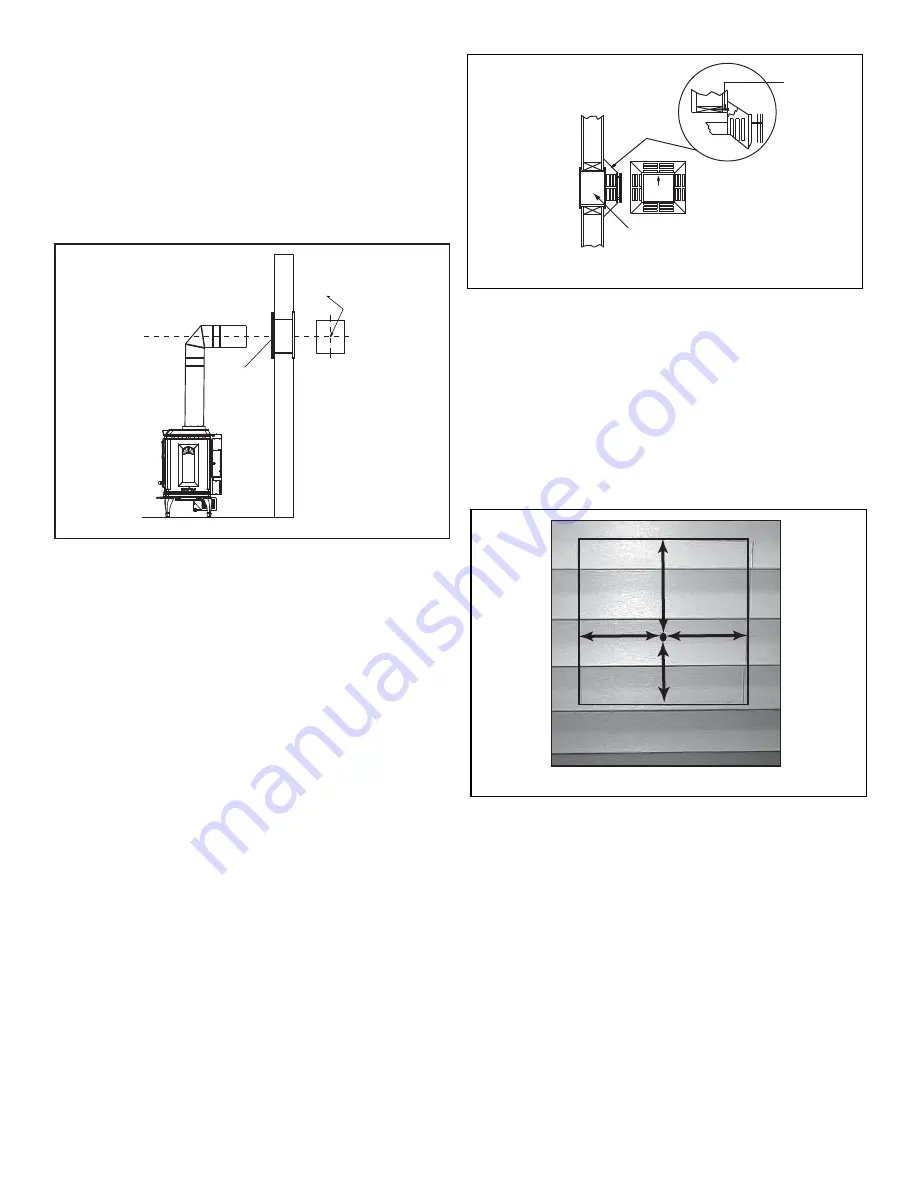

NOTES:

(1) The four wood screws provided should be replaced

with appropriate fasteners for stucco, brick, concrete,

or other types of sidings.

(2) A termination cap with a built-in vinyl standoff is highly

recommended on a building with vinyl siding. The pilot

hole will be 2 in. (51mm) closer to the bottom of the

square than the top. Using a framing square, draw a

14 in. x 14 in. (356mm x 356mm) square around the

pilot hole. See

Figure 5.7

.

8 in.

(203mm)

7 in.

(178mm)

7 in.

(178mm)

6 in.

(152mm)

Figure 5.6

Figure 5.7

Figure 5.5

CENTER

LINE

CENTER OF

HOLE

WALL

THIMBLE

CENTER

LINE

Step 3.

For installations using a round support box/wall thimble

(check pipe manufacturer's instructions), mark the wall for

a 10 in. x 10 in. (254mm x 254mm) square hole. The

center of the square hole should line up with the center line

of the horizontal pipe, as shown in

Figure 5.5

. Cut and

frame the hole in the exterior wall where the vent will be

terminated. If the wall being penetrated is constructed of

non-combustible material, i.e. masonry block or concrete,

a 7 in. (178mm) diameter hole is acceptable.

Step 4.

Position the horizontal termination cap in the center of the 10

in. x 10 in. (254mm x 254mm) square hole and run a bead

of non-hardening mastic around its outside edges, so as to

make a seal between it and the wall, attach termination cap

to the exterior wall with the four wood screws provided. The

arrow on the vent cap should be pointing up (

Figure 5.6

).

(

NOTE:

Some termination caps may cause the vent

pipe to be off center on flashing.). Ensure that proper

clearances to combustible materials are maintained. If

you are not using an approved termination cap with

a built-in standoff on a building with vinyl siding, a

vinyl siding standoff should be installed between the

termination cap and the exterior wall (

Figure 5.8

, on

the next page). Follow manufacturer’s instructions for

attaching the vinyl siding standoff to the horizontal

termination cap. The vinyl siding standoff prevents

excessive heat from possibly melting the vinyl siding

material. Remove siding from the area where the

standoff will be located.

WARNING !

The vent terminal cap shall not be recessed

into a wall or siding

.