26

Heat & Glo • TIARA II-B • 7011-148 Rev. G • 10/12

7

Electrical Information

A. Recommendation for Wire

C. Standing Pilot Ignition System Wiring

See B5 below for recommended maximum lead length (two

wire) when using wall thermostat/switch.

B. Connecting to the Appliance

This appliance

DOES NOT

require 110 VAC supply for

operation. A wiring diagram is shown in

Figure 7.1

on the

next page.

This appliance is equipped with a millivolt control valve.

NOTE:

This appliance must be electrically wired and

grounded in accordance with local codes or, in the absence

of local codes, with

National Electric Code ANSI/NFPA

70-latest edition

or the

Canadian Electric Code, CSA

C221.1.

Do not connect this appliance to a thermostat serving

any other appliance.

Bedroom installation in Canada requires this appliance

to be connected to a thermostat.

1. This appliance may be used with a wall switch, wall

mounted thermostat and / or a remote control.

2.

If using thermostat, use one compatible with a millivolt

gas valve system.

3.

Follow parameters for locating thermostat (see individ-

ual thermostat instructions) to ensure proper operation

of appliance.

4.

Use low resistance thermostat wire for wiring from igni-

tion system to the wall switch and thermostat.

5.

Use the following chart for wire sizing.

6. Keep wire lengths as short as possible by removing

any excess wire length.

7.

Low voltage and 110 VAC voltage cannot be shared

within the same wall box.

Wire Size

Max. Length

16 gauge

65 feet

18 gauge

40 feet

20 gauge

25 feet

22 gauge

18 feet

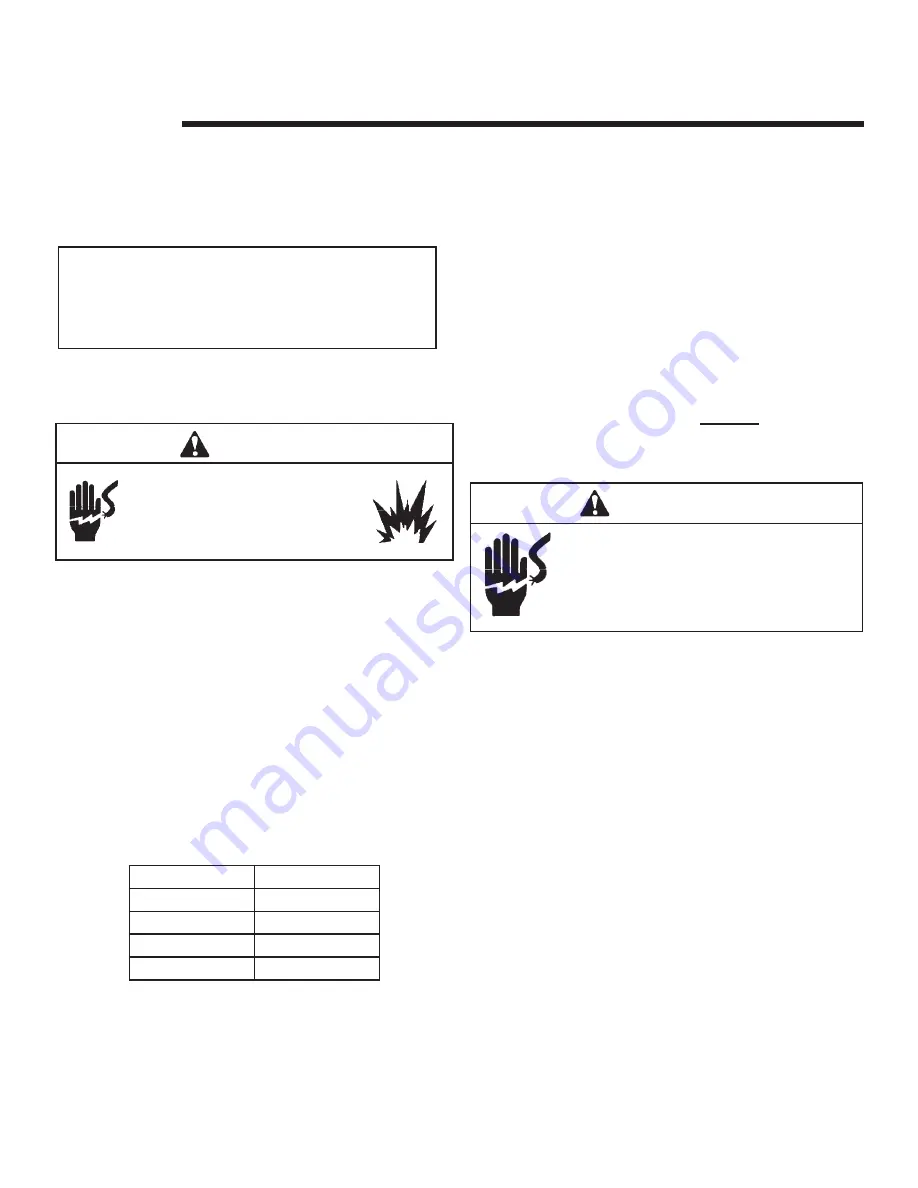

WARNING

Shock hazard.

• This appliance is equipped with a three

This appliance is equipped with a three

pronged (grounding) plug for your protection

pronged (grounding) plug for your protection

against shock hazard and should be plugged

against shock hazard and should be plugged

directly into a prop

directly into a properly grounded three prong

receptacle. Do not cut or remove the grounding

prong from this plug.

WARNING

Wire 110v to electrical junction box.

Do NOT wire 110v to the valve.

Do NOT wire 110V to wall switch.

• Incorrect wiring will damage millivolt

systems.

8. Ensure the thermostat is mounted level for accurate

readings.

9.

The thermostat should be mounted on an inside wall

and not in direct line with the appliance convection air.

10. If the thermostat is located too close to the appliance,

you may need to set the temperature setting slightly

higher to maintain the desired temperature in your

home.