4/20/11

Heat & Glo • NorthStar EPA Fireplace • 480-1081E

Page 57

Warning Fire Risk!

Maintain clearances

Use only non-combustible material below standoffs, mate-

rial such as cement board is acceptable.

Framing or finishing material used on the front of, or in

front of, the appliance closer than the minimums listed,

must be constructed entirely of non-combustible

materials (i.e., steel studs, concrete board, etc.).

60 in.

(1524mm)

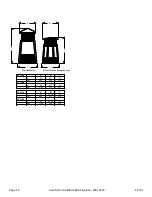

Mantel

Clearances are

from bottom of

appliance to lower

edge of mantel or

trim

Trim

48 in.

(1219mm)

A combustible mantel may be positioned no lower than 60 in.

(1524mm) from the base of the fireplace.

The combustible mantel may have a maximum depth of 12 in.

(305mm). Combustible trim pieces that project no more than

3/4 in. (19mm) from the face of the fireplace can be placed

no closer than 6 in. (152mm) from the side of the decorative

front. See Figure 10.9

Combustible trim must not cover:

• the metal surfaces of the fireplace

• where the non-combustible board is placed over the metal

surfaces

• the space between the metal face of the fireplace and framing

members

Figure 10.9 Mantel Specifications

WARNING! Fire Risk

Hearth & Home Technologies is not responsible for discol-

oration, cracking or other material failures of finishing ma-

terials due to heat exposure or smoke.

• Choose finishing materials carefully.

F. Mantel

Refer to page 37 for clearance requirements

• Non-Combustible Sealant Material

Sealants which will not ignite and burn: Super Calstick

After completing the framing and applying the facing mate-

rial (drywall) over the framing, a bead of non-combustible

sealant must be used to close off any gaps at the top and

sides between the fireplace and facing to prevent cold air

leaks. Large gaps can be bridged with fiberglass rope gas-

ket.

Only non-combustible materials may be used to cover the

metal fireplace front.

• Cardboard OR Metal Template

A cardboard template of the front is printed on the outside of

the shipping box. It measures 1/8 in. (3 mm) bigger all the

way around than the actual front. Cut out the template

along the outside of the line for use in your installation.

A metal template is also available for more durable continued

use remaining accurate over time. See page 64 for catalog

number.