Heat & Glo • PRIMO48, PRIMO48ST, PRIMO60, PRIMO60ST, PRIMO72, PRIMO72ST Owner’s Manual • 2310-971 Rev. G • 9/15

8

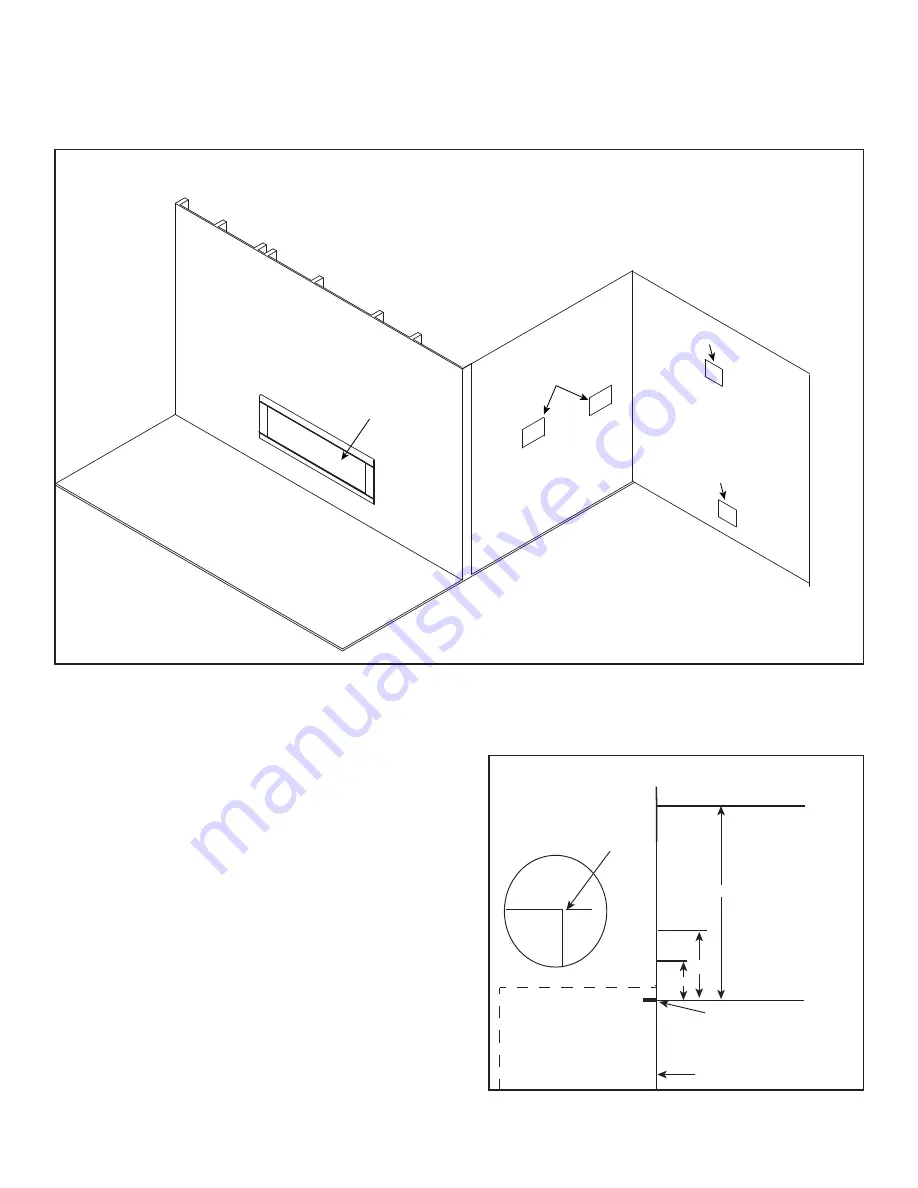

Figure 3.1 General Operating Parts

B. General Operating Parts

C. Fuel Speci

fi

cations

WARNING! Risk of Fire or Explosion!

Appliance must

be set up for compatible gas type!

• This appliance is designed to operate on either natural

gas or propane. Make sure the appliance is compatible

with gas type selected for installation site.

• Conversions must be made by a qualified service

technician using Hearth & Home Technologies speci

fi

ed

and approved parts.

Figure 3.1 references the general operating parts of the

appliance and the section of this manual in which they are

discussed.

BARRIER GLASS & FIREBOX GLASS

SECTION 4

OPTIONAL

HEAT-ZONES

SECTION 3 & 4

OPTIONAL HEAT-OUT-PRIMO

SECTION 6

POWER VENT

SECTION 3 & 4

OUTSIDE WALL

INSIDE WALL

Figure 3.2. Wall Surface Temperatures Above Appliance

MEASUREMENTS FROM

TOP EDGE OF THE OPENING

6 in.

TO CEILING

110°F

APPLIANCE FRONT

31 in.

FIREPLACE

OPENING

100°F

20 in.

D. Wall Surface/TV Guidelines

Note:

The PRIMO must be power vented using

either a PVI-SLP System or a PVLP-SLP System

AND a PowerFlow

TM

Heat Management System.

WARNING! Risk of Fire!

Either the HEAT-ZONE-PRIMO or the

HEAT-OUT-PRIMO PowerFlow™ Heat Management system

must remain ON during operation of the appliance. Overheating

will occur. Appliance will shut down.