Page

7

7076-260B · April 8, 2015

A. Positioning Your Wood Burning Stove

The wood burning stove must be set up so the stove, fl ue

connection, fl ue pipe, and chimney system can be cleaned

and serviced. Consideration should also be made when

locating the appliance in the home due to the supply of

combustion air requirements. Depending on the chosen

installation method, supplied combustion air may be taken

from the outside using the adapters provided, or through

the back of the unit by removing the cover plate on the

inlet hole. (To remove the cover or install the outside air

adapter, remove the back panel. The cover plate is located

near the bottom and retained with four screws.)

Out of the box, the appliance without the additional weight

of the venting system or fuel load weighs nearly 100

kilograms. Make considerations for the weight of the

system when locating the unit in the desired location. If

the load bearing characteristics of the structure are diffi cult

to determine or there is concern that the structure will not

adequately support the system, a distribution plate should

be used. Contact your Radius Wood Stove dealer with

questions.

B. Vertical Venting & Combustion Air

When venting the appliance vertically, follow the venting

manufacturer’s instructions and requirements. Slip the

cover ring down the fl ue and set on top of the appliance.

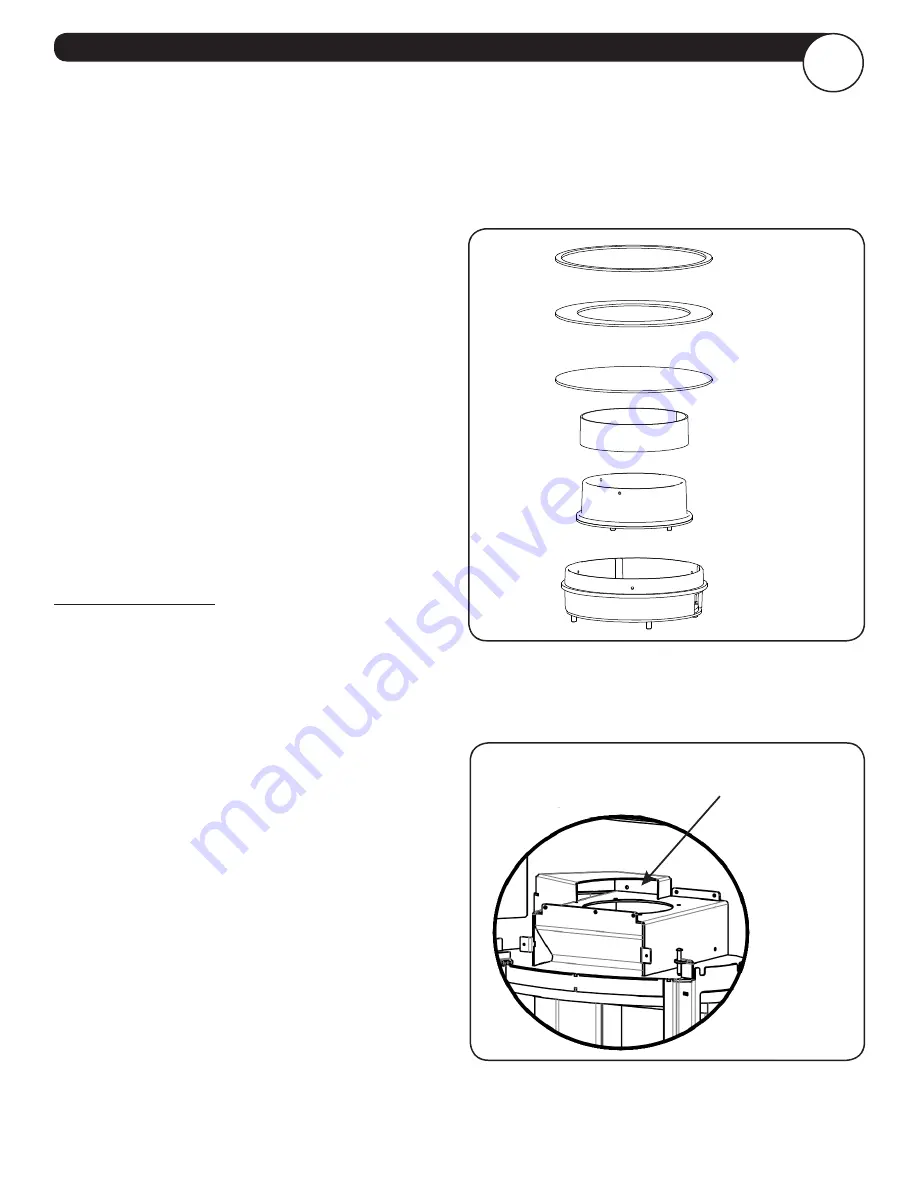

Vertical Venting Options

(Fig. 7.1)

Standard 150mm Venting: E, B, F

Coaxial venting: F, E, D, A

(Use the items indicated for your installation. Use the bolts

provided to attach the components in the order shown.)

When installing F:

•

- If installing outside combustion air, turn F to cover the

opening at the top of the combustion air plenum.

•

- If using room combustion air or coaxial venting, turn

F to leave the opening at the top of the combustion air

plenum open.

(The outside air connection is located on the lower back

of the stove. The 75mm adapter is included in the

component pack.)

C. Horizontal Venting

When venting the unit horizontally, remove the back panel

of the unit. Next, remove the cast fl ue attachment ring in

the top of the appliance by removing the four bolts used

to secure it in shipping. Remove the rear cover plate that

can be seen in the back of the unit once the back panel

is removed. Install the rear cover plate over the vertical

outlet hole in the top of the unit using the four bolts that

were used to secure the cover plate when installed on the

rear of the unit. Install the cast fl ue attachment ring on the

rear of appliance using four bolts. Knock out the panel on

the back panel so the fl ue attachment ring can slip through

it. Attach the back panel back onto the appliance using

the same fasteners. Install the venting per the venting

manufactures specifi cations. Place the top cover plate

(item “C” in Fig. 7.1) from the component pack over the

hole in the top of the appliance for a fi nished look.

INSTALLATION & ASSEMBLY

Opening at the top of the

combustion air plenum

A

B

C

D

E

F

Fig. 7.1

Fig. 7.2