26

Table 8.2

B. Using Offsets/Returns

• Use an offset/return to bypass overhead obstructions.

• An offset and return can be used as a single entity or separated by chimney section(s).

WARNING! Risk of Fire! DO NOT use offset/returns greater than 30°. Chimney draft will be restricted and could cause

overheating and fire.

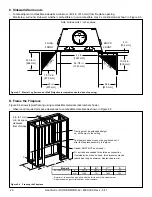

• Measure the shift needed to avoid the overhead obstruction. Refer to dimension A in Figure 8.3.

• Find the appropriate A dimension listed in Table 8.2.

• The B dimension coinciding with the A dimension measurement in Table 8.2 represents the required vertical clearance

needed to complete the offset/return.

• Read across the chart to find the number of chimney sections/model numbers needed between the offset and return.

A

B

1-1/4 in. (32 mm)

OVERLAP

Figure 8.3 Chimney Offset/Return

Heat & Glo • RUTHERFORD-42 • 4059-309 Rev L • 5/11

A

B

SL1106 SL1112 SL1118 SL1136 SL1148

in.

mm

in.

mm

4 7/8

124

17 7/8

454

-

-

-

-

-

7 1/4

184

22

559

1

-

-

-

-

9 3/4

248

26 1/8

664

2

-

-

-

-

10 1/4

260

27 1/4

692

-

1

-

-

-

12 3/4

324

31 3/8

797

1

1

-

-

-

13 1/4

337

32 3/8

822

-

-

1

-

-

15 3/4

400

36 5/8

930

-

2

-

-

-

18 1/8

460

40 3/4

1035

1

2

-

-

-

18 3/4

476

41 3/4

1060

-

1

1

-

-

21 3/4

552

47

1194

-

-

2

-

-

22 1/4

565

4 8

1219

-

-

-

1

-

24 3/4

629

52 1/8

1324

1

-

-

1

-

27 3/4

705

57 3/8

1457

-

1

-

1

-

28 1/4

718

58 3/8

1483

-

-

-

-

1

30 3/4

781

62 1/2

1588

1

-

-

-

1

33 3/4

857

67 3/4

1721

-

1

-

-

1

36 3/4

933

73

1854

-

-

1

-

1

39 3/4

1010

78 1/8

1984

-

-

-

2

-

41 1/8

1045

82 3/8

2092

1

-

-

2

-

45 3/4

1162

88 1/2

2248

-

-

-

1

1

48 1/8

1222

92 3/4

2356

1

-

-

1

1

51 3/4

1314

98 7/8

2511

-

-

-

-

2

Proper assembly of air cooled chimney parts results in an overlap of chimney joints

of 1-1/4 in. (32 mm). Effective length is built into this table.

Example:

Your “A” dimension from Figure 8.3 is 14 1/2 in. (368

mm). Using Table 8.2 the dimension closest to, but not

less than 14 1/2 in. (368 mm) is 15 3/4 in. (400 mm) using

a 30° offset/return.

You determined from the table that you would need

36 5/8 in. (930 mm) (Dimension “B”) between the offset

and return.

The chimney component that best fits your application is

two SL1112s.